ASTM B135 C 27000 63-37 Lead Free Brass

Product Details:

- Type Lead Free Brass Rod

- Material Brass

- Grade ASTM B135

- Tolerance h9/h11

- Alloy C27000

- Temper H02 (Half Hard)

- Length 3 meter

- Click to View more

ASTM B135 C 27000 63-37 Lead Free Brass Price And Quantity

- 300 Kilograms

- 380.00 - 480.00 INR/Kilograms

ASTM B135 C 27000 63-37 Lead Free Brass Product Specifications

- Lead Free Brass Rod

- h9/h11

- 3 meter

- ASTM B135

- Varies as per dimension

- Round

- H02 (Half Hard)

- 10 mm to 100 mm

- Golden Yellow

- Brass

- C27000

ASTM B135 C 27000 63-37 Lead Free Brass Trade Information

- 60000 Kilograms Per Month

- 3 Week

Product Description

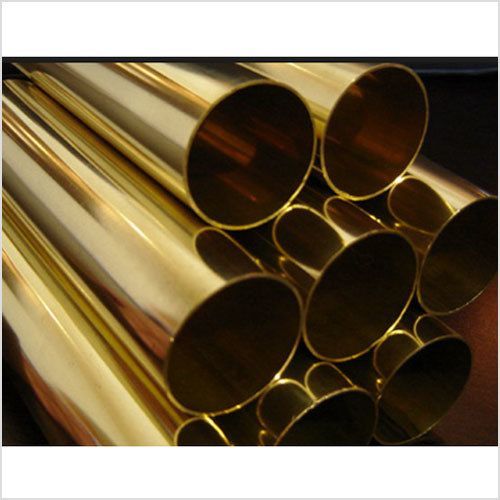

ASTM B135 C 27000 63-37 Lead Free Brass

Being the leaders in the industry, we are engaged in manufacturing and exporting a varied

assortment of 70/30 Brass Tubes, Condenser Tubes. Precisely manufactured using premium grade

raw materials that are sourced from trusted & reliable dealers, the brass tubes offered by us are used

in various industries including, sugar & general engineering. Our 70/30 Brass Tubes are sturdy in

construction, easy to install, durable, corrosion proof and offered at nominal costs.

Application Area: Sugar Industries, Plumbing, Furniture, Hand Pumps, Ammunitions, General Engineering.

Technical Specifications :

| Specification : | |

| 70/30 Brass |

|

| S407/81 (SUGAR ALLOY I) | |

| Chemical Requirements | CuZn30As |

| Copper + Incidental Ni | 68.5 - 71.5% |

| Lead | 0.07% max |

| Arsenical | 0.02 to 0.06% |

| Iron | 0.06% max |

| Other Imp. | 0.30% max |

| Zinc | Remainder |

| Physical Properties | ||

| Condition | T.S. Mpa | Hardness (HV5) |

| Annealed (O) | 285 min | 75 max |

| Temper Annealed (TA) | 300 min | 80-110 |

| Hard (H) | 400 min | 135 min |

Further Tests :

Drift Test

Flattening Test

MN Test

Hydraulic Test

Uses : Condenser & heat exchangers tubes mainly for sugar plants, liner material for hand pumps

Comprehensive Material Standards

The rods adhere to ASTM B135 standards and are classified as C27000 brass alloy. With a lead-free formulation, these rods promote safer usage in applications where lead contamination is a concern. Each rod is meticulously checked to guarantee consistent quality, offering reliable hardness and performance for industrial needs.

Optimal Physical and Chemical Properties

With a melting point between 900C and 940C, density at 8.47 g/cm, and a hardness range of 75110 HV, these brass rods boast robust mechanical properties. The polished, bright surface finish enhances their appeal for decorative uses, while offering excellent corrosion resistance, critical for demanding environments.

Flexible Application in Multiple Industries

Thanks to their cold drawn processing and versatile dimensions, these brass rods cater to general engineering, electrical, and decorative sectors. Their golden yellow color and standardized shape make them attractive for both structural and aesthetic purposes, ensuring adaptability across industry requirements.

FAQs of ASTM B135 C 27000 63-37 Lead Free Brass:

Q: How are ASTM B135 C27000 lead free brass rods manufactured?

A: These rods are produced through a cold drawn process, which enhances their mechanical strength and refines the grain structure. The process helps provide uniformity and precision, resulting in rods with bright, polished finishes and consistent hardness.Q: What makes C27000 brass rods suitable for electrical and decorative applications?

A: C27000 brass rods offer 27% IACS conductivity and a golden yellow color, making them ideal for electrical components as well as aesthetically appealing decorative items. Their lead-free composition also ensures safety in sensitive applications.Q: When should I opt for lead free brass rods instead of standard brass rods?

A: Lead free brass rods should be chosen when environmental safety is a concern, especially in applications that involve potable water, food contact, or situations where lead exposure must be minimized for regulatory or health reasons.Q: Where are these brass rods commonly used?

A: They are often used in industries such as general engineering, electrical manufacturing, and the decorative sector. Their attributes also make them suitable for the fabrication of precision components and fittings.Q: What benefits do the corrosion resistance and polished finish offer?

A: The excellent corrosion resistance ensures longevity even in harsh environments, while the polished, bright surface delivers both functional and aesthetic value. This makes the rods suitable for outdoors and visually prominent installations.Q: How can users specify their order of these brass rods?

A: Customers can select the necessary diameter (from 10 mm to 100 mm), a standard length of 3 meters, and require tolerance h9/h11. Weight will vary according to the dimensions chosen and rods are available for export and supply from India.Q: What are the key advantages of the H02 (half hard) temper in these brass rods?

A: The H02 temper provides a balance between strength and workability, allowing the rods to be formed or machined as needed while maintaining essential mechanical properties for demanding engineering tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in '63/37 Lead Free Brass Tubes & Rods' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |