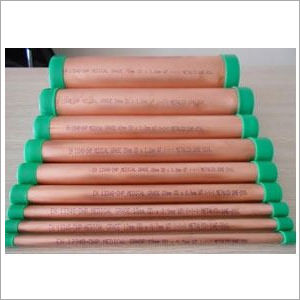

Medical Grade Copper Pipes

Product Details:

- Outer Diameter 12 mm to 54 mm

- Size Various sizes as per requirement

- Finish Smooth, bright finish

- Surface Treatment Cleaned and degreased

- Diameter 12 mm to 54 mm

- Condition New

- Cross Dimension Circular

- Click to View more

Medical Grade Copper Pipes Price And Quantity

- 500 Kilograms

- 400.00 - 1000.00 INR/Kilograms

Medical Grade Copper Pipes Product Specifications

- High tensile strength

- Cleaned and degreased

- Copper

- Smooth, bright finish

- 12 mm to 54 mm

- Round

- New

- Circular

- Annealed (soft) and drawn (hard)

- 0.7 mm to 2 mm

- Medical Grade

- Various sizes as per requirement

- Custom lengths available up to 6 meters

- 12 mm to 54 mm

Medical Grade Copper Pipes Trade Information

- 150 Kilograms Per Month

- 3-4 Week

Product Description

At Metal Alloys Corporation we proudly manufacture marked Medical Grade Copper Pipes used in Medical Gas Distribution system. Uninterrupted Medical Gas supply is a necessity in hospitals (ICCU, Operation Theater, Wards, Nursery etc). Pipes facilitate this in most effective manner.Marked medical grade copper tubes are manufactured as per EN13348 / BS EN 1057 specifications. The pipes are manufactured under thorough inspections and quality control measures. Marked medical grade copper tubes are available in size range 6mm to 108mm OD, 0.6mm to 2.0mm wall thickness in Half Hard/Hard conditions and Length 3 meter as per requirement.Pipes are subjected to Third Party Inspection agencies like Lloyds, SGS, TUV as per customer demand.

Precision Manufactured for Medical Gas Applications

Engineered to meet the stringent EN 13348 standard, our medical grade copper pipes are specifically designed for use in high pressure medical gas distribution systems. Each pipe is degreased, thoroughly cleaned, and finished to ensure a contaminant-free pathway for life-critical gases, all while maintaining optimal strength and reliability in demanding environments.

Custom Sizes and Superior Finish

Available in a range of diameters from 12 mm to 54 mm and wall thicknesses between 0.7 mm and 2 mm, our copper pipes can be tailored to meet your projects exact requirements. The pipes feature a smooth, bright outer surface, facilitating easy installation and compatibility with a range of connection methods. Custom lengths up to 6 meters further enhance flexibility.

FAQs of Medical Grade Copper Pipes:

Q: How are these medical grade copper pipes manufactured to ensure cleanliness and compliance?

A: Our pipes are manufactured using a rigorous process that includes thorough cleaning and degreasing after the drawing or annealing stage. They comply with EN 13348 standards, which mandate strict quality control for medical gas applications, ensuring removal of contaminants and reliable, safe use in hospitals and healthcare facilities.Q: What is the benefit of choosing these pipes for medical gas systems?

A: These pipes provide excellent corrosion resistance, high tensile strength ( 300 MPa), and a precise wall thickness tolerance of 0.05 mm, ensuring long-term reliability and safety when transporting medical gases under high pressure. The high conductivity and smooth internal finish also minimize energy losses and contamination risks.Q: When should I opt for annealed (soft) versus drawn (hard) copper pipes?

A: Annealed (soft) pipes are preferable when easy bending or manipulation during installation is required, while drawn (hard) pipes are chosen for projects that demand higher mechanical strength and rigidity. Selection depends on installation methods and system demands.Q: Where are these copper pipes typically used?

A: These pipes are predominantly used in the construction of medical gas infrastructures within hospitals, clinics, and healthcare facilities, as well as other projects requiring reliable, corrosion-resistant piping systems for high-pressure gas or fluid transfer.Q: What are the available size options and customization process for these pipes?

A: Pipes can be ordered in outer diameters from 12 mm to 54 mm, wall thicknesses ranging from 0.7 mm to 2 mm, and custom lengths up to 6 meters. Sizes can be specified as per project needs to ensure seamless integration and optimal performance.Q: How are the pipes packed to maintain quality during transport?

A: The pipes are bundled securely and fitted with protective end caps, guarding against contamination and mechanical damage during shipment and handling, thereby preserving their interior cleanliness and bright finish.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |