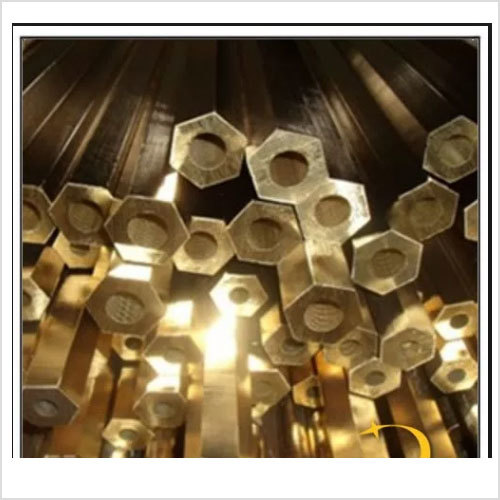

C36300 Copper Lead Zinc Alloy

Product Details:

C36300 Copper Lead Zinc Alloy Price And Quantity

- 400.00 - 1000.00 INR

- 500 Kilograms

C36300 Copper Lead Zinc Alloy Trade Information

- 150 Kilograms tons Per Month

- 3 to 4 Week

Product Description

C36300 alloy provides a lower lead brass alloy option that aids with the compliance strategies of manufacturers who seek an alternative that is not only COMPLIANT, but also COMPETITIVE and COMPATIBLE with standard free cutting and forgings alloys commonly used today.

| Equivalent Specifications: | |

| Specifications | Designation |

| ISO | CuZn37 |

| European | CW508L |

| BS | |

| JIS | C36300 |

| Russian | |

| Typical Applications : | |

| C33000 Low Leaded Brass |

|

| Advantages : | |

| C33000 Low Leaded Brass |

|

| Chemical Composition : | |||||

| Cu | Pb | Fe | P | Zn | |

| Min/Max | 61.0 - 63.0 | 0.25-0.70 | 0.15 (max) | 0.04-0.15 | Rem |

| Nominals | 63.00 | 37.00 | |||

| Mechanical Properties: | ||||

| Rod H02 | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation (%) | Hardness (Rb) |

| 65 | 45 | 20% | 75 | |

| Sizes Available : | ||

| Wire | 1mm To 8mm | |

| Hollow Rods | Min Bore Size 20 mm and Max OD 100 mm | |

| Round Rods | 6mm To 130 mm | |

| Hex | 5mm To 60mm | |

| Square | 4mm To 60mm | |

| Flat | 5mm Min Thickness and max Width 120mm | |

| Profiles / Sections | AS per Customer Drawing | |

| Billets | Up to 200 mm | |

| Ingots | AS per Specification | |

Superior Alloy Composition

C36300 Copper Lead Zinc Alloy features a balanced composition for optimum mechanical strength, machinability, and corrosion resistance. Its unique combination of copper, lead, and zinc makes it suitable for demanding industrial applications where performance and longevity are crucial.

Advanced Manufacturing Process

Using state-of-the-art extrusion techniques, the alloy is shaped into seamless, round tubes or rods. The polished finish enhances both functional performance and surface appearance, making it ideal for applications needing both durability and visual appeal.

Reliable Supply from India

As an exporter, manufacturer, and supplier based in India, we ensure consistent quality, timely delivery, and full compliance with global standards. Our seamless C36300 alloy products are distributed efficiently to clients worldwide, backed by professional after-sales support.

FAQs of C36300 Copper Lead Zinc Alloy:

Q: How is the C36300 Copper Lead Zinc Alloy produced?

A: The C36300 alloy is manufactured using extruded techniques, which involve forcing the alloy through a die to create seamless, round bars or tubes. The surface is then polished to enhance smoothness, appearance, and resistance to corrosion.Q: What are the main benefits of using extruded, seamless, and polished C36300 alloy?

A: Extruded, seamless C36300 alloy ensures superior strength and leak-proof performance, while the polished surface offers enhanced resistance to wear and oxidation. This combination results in dependable durability and an attractive finish for various applications.Q: When should I choose C36300 Copper Lead Zinc Alloy for my project?

A: C36300 is an excellent choice when you require a material with high machinability, pressure resistance, and excellent corrosion resistanceideal for plumbing, electrical, or mechanical engineering components.Q: Where can I source seamless, polished, round C36300 copper alloy products?

A: You can source these products from certified exporters, manufacturers, and suppliers in India who specialize in seamless C36300 alloy products tailored to specific application needs and international quality standards.Q: What is the typical process for exporting this alloy from India?

A: The export process involves quality inspection, precise packaging to prevent damage, and documentation for international shipping. Reputable suppliers coordinate logistics to ensure prompt and secure global delivery of C36300 alloy products.Q: How can C36300 Copper Lead Zinc Alloy be used in industry?

A: This alloy is widely used in manufacturing electrical connectors, plumbing fittings, mechanical components, and similar products requiring reliable conductivity, machinability, and structural integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Dezincification Resistant Brass' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |