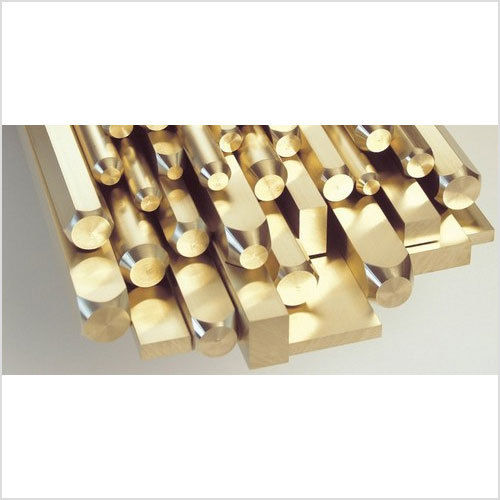

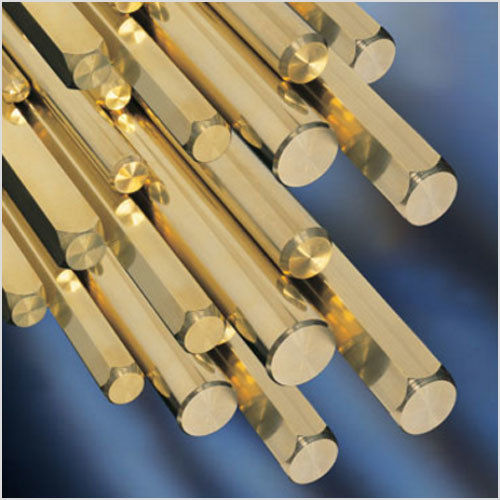

High Tensile Brass Rods

Product Details:

- Type High Tensile Brass Rod

- Material Brass

- Grade HT1/HT2

- Tolerance +/- 0.05 mm or as specified

- Alloy CuZn39Pb3

- Temper As per requirement (usually Hard/Half Hard)

- Length Up to 5 Meters or as specified

- Click to View more

High Tensile Brass Rods Price And Quantity

- 500 Kilograms

- 400.00 - 1000.00 INR/Kilograms

High Tensile Brass Rods Product Specifications

- CuZn39Pb3

- Round, Hex, Square

- Varies as per size and length

- Up to 5 Meters or as specified

- HT1/HT2

- 5 mm to 127 mm or customized

- High Tensile Brass Rod

- As per requirement (usually Hard/Half Hard)

- Golden Yellow

- Brass

- +/- 0.05 mm or as specified

High Tensile Brass Rods Trade Information

- 150 Kilograms Per Month

- 3 - 4 Week

Product Description

We are one of the leading manufacturers, exporters and suppliers of a premium quality assortment of High Tensile Brass Rods, Brass Extrusion Rods. Offered in different sizes, thicknesses and grades, these are valued for their excellent performance, high conductivity, durability, reliable operation and corrosion resistance. At par with the prerequisite industry standards, our High Tensile Brass Rods can be purchased by clients in standard & customized specifications and at cost effective rates.

| Specification : | |

| High Tensile Brass |

|

Specifics :

BS:1001

HT12472

IS:320 l & ll

| Chemical Requirements | HT1 | HT2 | |||

| Copper | 56.0 - 60.0% | 56.0 - 61.0% | |||

| Lead | 0.20 to 1.50% | 0.50 to 1.50% | |||

| Iron | 0.20 to 1.25% | 0.20 to 1.50% | |||

| Tin | 0.20 to 1.0% | 1.0% max | |||

| Aluminum | 0.2% max | 0.30 to 2% | |||

| Manganese | 0.25 - 2.0% | 0.50-2.0% | |||

| Total Imp. | 0.50% max | 0.50% max | |||

| Zinc | Remainder | Remainder | |||

| Physical Properties | |||||

| Condition | Size | T.S. MPa | EL% Min | T.S. MPa | EL% Min |

| As manufactured | All Size | 430 min | 20% | 460 min | 20% |

| Cold-worked & Stress | 10-40 | 480 min | 12% | 520 min | 12% |

| Relieved | 40 above | 500 min | 15% | ||

| Fabrication Properties | |||||

| Capacity for being | |||||

| Cold formed | Poor | Fair | |||

| Hot worked | Good | Good | |||

| Machinability Rating | 30% | 30% | |||

| Resistance to Corrosion | Excellent | Excellent | |||

| Suitability for soldering | Excellent | Fair | |||

| Uses | |||||

| HT1 is suitable for Soldering | |||||

| Ht2 is suitable for Machining | |||||

Premium Quality & Precision Engineering

Our High Tensile Brass Rods are designed for precision and reliability, produced to comply with international standards for guaranteed performance. With tight tolerance control and exceptional surface finish, these rods are suitable for delicate and heavy-duty applications alike. Custom sizes and lengths ensure adaptability to diverse project requirements.

Superior Corrosion Resistance & Versatility

Protection against harsh environments is ensured by the rods excellent corrosion resistance, which is critical for marine and electrical usage. Their superior machinability and high conductivity (minimum 23% IACS) make them ideal for intricate engineering work, while the golden yellow hue enhances the aesthetic appeal for visible fittings and components.

FAQs of High Tensile Brass Rods:

Q: How are High Tensile Brass Rods manufactured to ensure quality and precision?

A: High Tensile Brass Rods are produced using advanced extrusion and finishing processes, adhering to prominent standards such as IS 320, BS 2874, and EN 12164/12167. Strict quality control checks for dimensions, tensile strength, surface finish, and tolerance (+/- 0.05 mm) guarantee consistent and reliable performance.Q: What applications are these brass rods best suited for?

A: These rods are widely used in automotive, electrical, marine, and engineering component manufacturing owing to their high tensile strength, superior machinability, and excellent corrosion resistance. Their versatility also makes them suitable for precision fittings and fasteners.Q: When should I choose High Tensile Brass Rods over other material options?

A: High Tensile Brass Rods are preferred when applications demand a combination of high strength, corrosion resistance, machinability, and conductivity. They are ideal in environments requiring longevity and reliability, such as marine or electrical installations.Q: Where are the rods typically supplied from, and what packing methods are used?

A: High Tensile Brass Rods are primarily exported and supplied by manufacturers and suppliers based in India. Packing is customized according to client requirements, typically using sturdy wooden boxes or bundles to ensure safe transportation and storage.Q: What is the benefit of the rods high machinability and bright surface finish in engineering?

A: The rods superior machinability allows for efficient and precise shaping, reducing production time and tool wear. Their bright, smooth finish enhances the appearance of final components while minimizing surface defects, ensuring both functional and aesthetic value.Q: How can the rods be customized to meet specific project requirements?

A: Customization is available for diameter (5 mm to 127 mm), length (up to 5 meters), shape (round, hex, square), grade (HT1/HT2), and temper (hard or half hard), with tolerances adjusted as per project specifications. Density and weight will vary according to chosen dimensions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Brass Rods & Profiles' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |