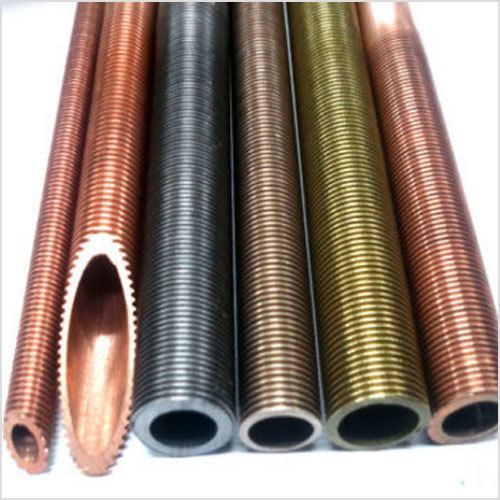

Finned Tubes Pipes

350.00 - 1000.00 INR

Product Details:

- Material Brass

- Type Galvanized

- Shape Round

- Technique Hot Rolled

- Surface Treatment Varnished

- Standard JIS

- Click to View more

X

Finned Tubes Pipes Price And Quantity

- 350.00 - 1000.00 INR

- 500 Kilograms

Finned Tubes Pipes Product Specifications

- Galvanized

- Hot Rolled

- Round

- JIS

- Varnished

- Brass

Finned Tubes Pipes Trade Information

- Per Month

- 2 Week

Product Description

METALCO offers different finned tubes: tension wound finned tubes, copper fin tubes, embedded finned tubes, extruded finned and low finned tubes. Tension would finned tubes are formed by winding a strip made of aluminium or copper around the tube under tension. The strip winding technology provides different types of fins: L-fin, LL fin, KL fin. Embedded fins (G fins) are made by winding aluminum or copper strip into a helical groove machined on the outer surface of the tube. Extruded Finned tubes are bimetallic tubes whose outer aluminum surface is finned by cold plastic deformation. The low finned tube is a finned tube obtained through plastic cold deformation. The method consists in realizing from a smooth tube, dins with a particular geomantic form without removing material; this plastic deformation causes an increment of heat exchange efficiency and allows to reduce the heat exchanger size. The finned tubes quality is assured by hydrostatic and pneumatic tests.

Brass, Copper-Nickel & Copper METALCO offers different finned tubes: tension wound finned tubes, copper fin tubes, embedded finned tubes, extruded finned and low finned tubes. Tension would finned tubes are formed by winding a strip made of aluminum or copper around the tube under tension. The strip winding technology provides different types of fins: L-fin, LL fin, KL fin.

Embedded fins (G fins) are made by winding aluminium or copper strip into a helical groove machined on the outer surface of the tube. Extruded Finned tubes are bimetallic tubes whose outer aluminium surface is finned by cold plastic deformation.

| Part Type | Finned Tubes |

| Unit Length | 500mm to 12000mm |

| Material | Copper |

| Type | External Finned Tubes |

| Type | Integrally Finned Tubes |

| Thickness | 1.25mm and above |

| Outer Diameter | 2.70mm to 38.10mm |

| Application | Gas Pipe |

| Country of Origin | Made in India |

Precision Manufacturing & Quality

Finned Tubes Pipes produced by us adhere strictly to JIS standards, utilizing a controlled hot rolled process for structural consistency. The addition of a varnished, galvanised surface on high-quality brass ensures each pipe meets demanding conditions while maintaining performance and reliability.

Versatile Applications

These pipes are ideally suited for industries like air conditioning, refrigeration, and oil refineries, where efficient heat exchange is vital. Their unique finned design maximizes surface area, promoting better thermal transfer and energy efficiency in challenging operational environments.

FAQs of Finned Tubes Pipes:

Q: How are your finned tubes pipes manufactured?

A: We manufacture our finned tubes pipes using the hot rolled technique, ensuring uniform thickness and surface integrity. The finishing process involves galvanization and varnishing for enhanced resistance to corrosion and wear.Q: What is the benefit of using varnished, galvanized brass finned tubes pipes?

A: The combination of brass material with galvanization and varnish provides excellent thermal conductivity, mechanical strength, and superior protection against environmental factors, making them ideal for long-term industrial use.Q: When should I choose finned tubes pipes with a round shape?

A: Round-shaped finned tubes are preferred when uniform heat transfer and easy installation are required, particularly in heat exchangers, HVAC systems, and similar settings where optimal fluid dynamics are essential.Q: Where can these finned tubes pipes be used?

A: These pipes are commonly used in a variety of industries, including petrochemical plants, power stations, oil refineries, and commercial refrigeration systems, due to their efficiency and durability.Q: What standard do your finned tubes pipes comply with?

A: Our pipes are manufactured in accordance with JIS (Japanese Industrial Standards), ensuring high-grade quality and international compatibility.Q: What is the process for exporting these pipes from India?

A: As a leading Indian exporter, we follow standardized export procedures, ensuring on-time delivery, proper documentation, and compliance with international standards for seamless global supply.Q: How does the finned design improve pipe performance?

A: The finned design increases the effective surface area, which boosts heat transfer rates, enhances efficiency, and reduces energy consumption in heat exchange applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |