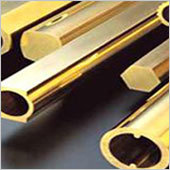

60/40 Brass Tubes

Product Details:

- Product Type Brass Round Tube

- Material 60/40 Brass (CuZn40)

- Shape Round

- Technique Hot Rolled

- Thickness 0.5mm To 10mm

- Alloy or Not Non-Alloy

- Outer Diameter 6mm To 130 mm

- Click to View more

60/40 Brass Tubes Price And Quantity

- 500 Kilograms

- 400.00 - 1000.00 INR

- Industrial, Plumbing, Electrical, Heat Exchangers

- Excellent

- Bright / Mirror / Polished

- 8.53 g/cm³

- Smooth / Cleaned

- Annealed / Hard / Half Hard

- As per requirement

- 290 - 450 MPa

- Seamless / Welded

- 930°C - 950°C

- 60% Copper, 40% Zinc

- Wooden Crate / Bundle Packing

60/40 Brass Tubes Product Specifications

- 0.5mm To 10mm

- 6mm To 130 mm

- ASTM B135, IS 407

- Round

- 6mm To 130 mm

- 1 meter To 6 meters

- Brass Round Tube

- Golden Yellow

- Hot Rolled

- Non-Alloy

- 60/40 Brass (CuZn40)

- Industrial, Plumbing, Electrical, Heat Exchangers

- Excellent

- Bright / Mirror / Polished

- 8.53 g/cm³

- Smooth / Cleaned

- Annealed / Hard / Half Hard

- As per requirement

- 290 - 450 MPa

- Seamless / Welded

- 930°C - 950°C

- 60% Copper, 40% Zinc

- Wooden Crate / Bundle Packing

60/40 Brass Tubes Trade Information

- 150 Kilograms tons Per Month

- 3 to 4 Week

Product Description

Founded and patented by English businessman George F. Muntz in 1832, Muntz Metal (C28000 or C280) is primarily used in architectural applications owing to its distinctive color. It is highly plastic metal at red heat that makes it ideal for pressing, stamping and hot forging. The metal alloy is also appreciated for high electrical and thermal conductivity, high ductility, high impact strength, good creep resistance, ease of welding, and low volatility under high vacuum.

Application Areas:

Architectural Panels

Large Architectural Trim

Structural Sheets

Door Frames

Decorative Hardware

Condenser Plate

Heat Exchanger Tube

Valve Stems

Brazing Rods

| Specification : | |

| 60/40 Brass |

|

Chemical Composition

| (%max., unless shown as range or min.) | ||||

| Cu | Fe | Pb | Zn | |

| Min./Max. | 59.0-63.0 | 80 - 83.0 | 0.2 | Rem. |

| Nominal | 60 | - | - | 40 |

| Physical Properties | ||

| Product Property | US Customary | Metric |

| Coefficient of Thermal Expansion | 11.6 ·10-6 per oF (68-572 F) | 20.9 · 10 6? per °C (20-300 C) |

| Density | 0.303 lb/in3 @ 68 F | 8.39 gm/cm3 @ 20 C |

| Electrical Conductivity | 28 %IACS @ 68 F | 0.164 MegaSiemens/cm @ 20 C |

| Electrical Resistivity | 37.0 ohms-cmil/ft @ 68 F | 6.15 microhm-cm @ 20 C |

| Melting Point Liquid US | 1660 F | 904 C |

| Melting Point Solid US | 1650 F | 899 C |

| Modulas of Elasticity in Tension | 15000 ksi | 103400 MPa |

| Modulas of Rigidity | 5600 ksi | 38610 MPa |

| Specific Gravity | 8.39 | 8.39 |

| Specific Heat Capacity | 0.09 Btu/lb/°F @ 68 F | 377.1 J/kg · °K at 293 K |

| Thermal Conductivity | 71.0 Btu · ft/(hr · ft2 ·°F) @ 68 F | 1229.9 W/m · °K at 20 C |

Versatile Applications Across Industries

60/40 Brass Tubes are ideal for industrial machinery, plumbing systems, electrical installations, and heat exchangers, thanks to their excellent mechanical and corrosion-resistant properties. Their adaptability to varied environments makes them a preferred choice for industries that require durability and efficiency along with an attractive, polished appearance.

Strict Adherence to International Standards

Every tube is produced to meet ASTM B135 and IS 407 standards, ensuring uniformity and reliability across all batches. These standards also guarantee the mechanical properties, composition, and finishes, making our brass tubes suitable for both domestic and international projects.

Quality Manufacturing and Customization

Choose from seamless and welded production processes, a range of finishes, and a selection of tempers (annealed, half-hard, hard) to suit your specific requirements. Tubes are available in custom lengths, diameters, and packing types, ensuring every order is tailored to your projects needs.

FAQs of 60/40 Brass Tubes:

Q: How are 60/40 Brass Tubes manufactured?

A: These brass tubes are produced using either the seamless or welded technique. Both processes start with 60% copper and 40% zinc to ensure a consistent CuZn40 composition. Tubes are then hot-rolled and treated for smooth or polished finishes before packaging in wooden crates or bundles.Q: What are the main applications of 60/40 Brass Tubes?

A: 60/40 Brass Tubes are extensively used in industrial equipment, plumbing systems, electrical fittings, and heat exchangers, owing to their excellent tensile strength, corrosion resistance, and aesthetic appeal.Q: When should I consider using annealed, hard, or half-hard temper brass tubes?

A: The temper depends on your application requirements: annealed tubes offer greater flexibility for bending and forming, hard tubes provide maximum strength and durability, and half-hard variants strike a balance between workability and structural integrity.Q: Where are your brass tubes exported and supplied from?

A: We manufacture and export 60/40 Brass Tubes from India, serving clients globally in industries such as construction, electrical, plumbing, and manufacturing.Q: What are the benefits of using 60/40 Brass Tubes?

A: These tubes deliver excellent corrosion resistance, high tensile strength (290450 MPa), and a sleek, golden yellow finish. Their high-quality manufacturing ensures reliable performance across a broad range of industrial and commercial applications.Q: How should the brass tubes be stored and packed for transit?

A: Tubes are packed in sturdy wooden crates or bundle packaging for safe transportation and storage, preventing damage and maintaining the finish and straightness during transit.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Lead Free Brass Tubes' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |