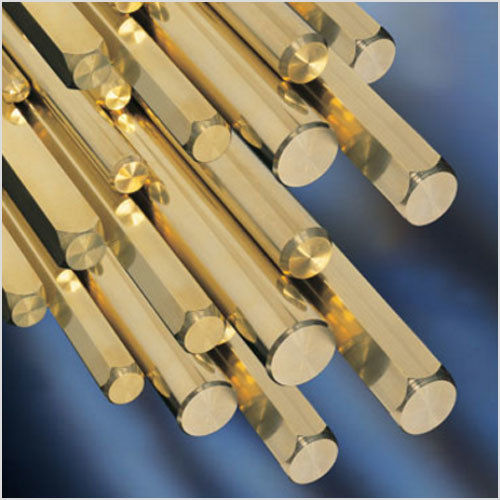

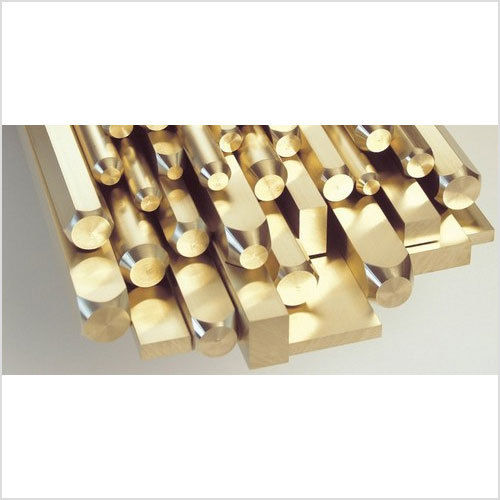

Forging Brass Rods

Product Details:

- Type Forging Brass Rods

- Material Brass

- Grade IS 319 / IS 4413 / ASTM B16

- Tolerance +/- 0.05 mm

- Alloy CuZn39Pb3 (CW614N)

- Temper Annealed / Half Hard / Hard

- Length 2 m to 6 m (customizable)

- Click to View more

Forging Brass Rods Price And Quantity

- 400.00 - 1000.00 INR

- 500 Kilograms

Forging Brass Rods Product Specifications

- +/- 0.05 mm

- Round / Hex / Square

- IS 319 / IS 4413 / ASTM B16

- Annealed / Half Hard / Hard

- 2 m to 6 m (customizable)

- Brass

- Forging Brass Rods

- CuZn39Pb3 (CW614N)

- Yellowish Golden

- As per dimensions

- 6 mm to 80 mm

Forging Brass Rods Trade Information

- 150 Kilograms tons Per Month

- 3 to 4 Week

Product Description

Forging Brass Rods

Our esteemed clients can avail from us a wide gamut of Forging Brass Rods, Extruded Brass Rods which have gained appreciation for it's international quality standards. Available in various sizes, thicknesses and specifications, these brass rods are largely used in various industries. Our competitively priced Forging Brass Rods are acknowledged for their high tensile strength, durable finish standards, corrosion resistance and sturdy designs.

Technical Specifications :

BS:218

IS3488

IS:6922

BS2874 CZ122

CuZn 38Pb1

1.5

| Chemical Requirements | CuZn42Pb2 | CuZn40Pb2 |

| Copper | 56.5 - 60.0% | 57.0 - 59.0% |

| Lead | 0.60 to 2.0% | 1.5 to 2.5% |

| Iron | 0.30% max | 0.40% max |

| Total Imp. Excl. Iron | 0.20% max | 0.70% max |

| Zinc | Remainder | Remainder |

| Physical Properties | ||

| Tensile Strength | 380 Mpa Min | 40 kg/mm2 Min. |

| Elongation % | 25% Min | 18% Min. |

| Izod Value | - | 2.0 KJ min |

| Fabrication Properties | ||

| Capacity for being | ||

| Cold worked | Poor | Poor |

| Hot formed | Excellent | Excellent |

| Hot forgeability rating | 100% | 100% |

| Machinability Rating | 80% | 80% |

| Suitability for soldering | Excellent | Excellent |

| Suitability for Brazing | Good | Good |

| Uses | |

| Forged Components, Industrial Valves, Defense components, Watch Case, Automobile Valves Components | |

Versatile Brass Rods for Multiple Industrial Needs

Forging Brass Rods are engineered for a spectrum of applications, ranging from electrical fittings and plumbing to precision machining and fabrication. Their robust composition ensures durability and adaptability across different settings, making them a preferred choice among manufacturers, exporters, and suppliers in India.

Exceptional Surface Finish and Customizable Options

With a bright and polished surface finish, these rods provide both aesthetic appeal and functional reliability. Customers can select from various shapesround, hex, or squareand request customized sizes to meet specific project requirements, all while maintaining stringent tolerances.

Premium Alloy and Excellent Machinability

Made from CuZn39Pb3 (CW614N) alloy, Forging Brass Rods feature up to 3% lead for enhanced machinability. Their superior corrosion resistance and range of tempers make them suitable for demanding and diverse industrial environments.

FAQs of Forging Brass Rods:

Q: How are Forging Brass Rods typically used in industry?

A: These rods are primarily used in forging and machining processes, as well as in producing electrical fittings and plumbing components. Their excellent corrosion resistance and machinability make them suitable for demanding applications across sectors such as electronics, construction, and fabrication.Q: What is the process for customizing the size of Brass Rods?

A: Customers can specify the required length (between 2 m and 6 m) and diameter (6 mm to 80 mm) according to their project. The rods are manufactured to these exact dimensions, with a tolerance of +/- 0.05 mm, ensuring precise fit and compatibility for any design.Q: When should I choose Brass Rods with a bright or polished surface finish?

A: A bright or polished finish is ideal when both corrosion resistance and aesthetic appeal are important, such as in visible plumbing installations, decorative fittings, and high-end electrical components. This finish also aids in achieving smoother processing during machining.Q: Where are these Forging Brass Rods primarily supplied from?

A: Forging Brass Rods are exported, manufactured, and supplied predominantly from India, meeting international quality standards including IS 319, IS 4413, and ASTM B16. Their reliable production and export make them accessible for global industrial applications.Q: What advantages does the CuZn39Pb3 (CW614N) alloy offer in Brass Rods?

A: This alloy combines copper, zinc, and up to 3% lead, resulting in rods with superior machinability and excellent corrosion resistance. The presence of lead enables intricate fabrication while maintaining strength and durability for long-term use.Q: How does the packaging ensure the quality and safety of Brass Rods during delivery?

A: Packaging options include bundles wrapped in plastic or sturdy wooden boxes, protecting the rods from physical damage, moisture, and contamination during transit. This ensures that the rods arrive in optimal condition for immediate use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Brass Rods & Profiles' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |