BS 2872 CZ108 Riveting Leaded Brass

Product Details:

- Type Riveting Leaded Brass

- Material Brass

- Grade BS 2872 CZ108

- Tolerance Standard tolerance 0.01 mm

- Alloy CZ108

- Temper Quarter Hard (1/4H) / Half Hard (1/2H)

- Length Custom / Standard lengths up to 6 meters

- Click to View more

BS 2872 CZ108 Riveting Leaded Brass Price And Quantity

- 500 Kilograms

- 400.00 - 600.00 INR/Kilograms

BS 2872 CZ108 Riveting Leaded Brass Product Specifications

- Custom / Standard lengths up to 6 meters

- Typical range 10 mm to 100 mm

- Riveting Leaded Brass

- BS 2872 CZ108

- Standard tolerance 0.01 mm

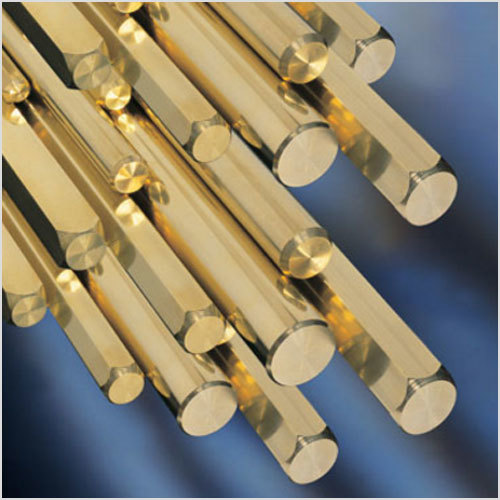

- Yellowish-Golden

- Brass

- Round Bar

- Variable as per size specification

- Quarter Hard (1/4H) / Half Hard (1/2H)

- CZ108

BS 2872 CZ108 Riveting Leaded Brass Trade Information

- 50000 Kilograms Per Month

- 3 Week

Product Description

BS 2872 CZ108 Riveting Leaded Brass

e are one of the well recognized manufacturers and exporters of a sturdily designed array of Riveting Brass Rods. These are machined in sync with the industrial norms using modern machinery and excellent grade raw materials. Available in diverse specifications and at pocket friendly prices, our Riveting Brass Rods are well known across the global market owing to their incomparable performance, high conductivity, corrosion resistance and low maintenance.

| Specification : | |

| Riveting Brass |

|

| Chemical Requirements | CuZn40 | ||

| Copper | 59.0 - 62.0% | ||

| Lead | 0.75% max. | ||

| Iron | 0.10% max. | ||

| Total Imp. Excl. Iron | 0.300% max. | ||

| Zinc | Remainder | ||

| Physical Properties | |||

| Condition | Size mm | T.S.Kg/mm2 | EL% Min |

| Annealed (O) | 1.2 & above | 28 min. | 30% |

| As Manufactured | 1.2 & above | 35 min. | 25% |

| Fabrication Properties | |||

| Capacity for being | |||

| Machinability Rating | 55% | ||

| Bending | Excellent | ||

| Riveting | Excellent | ||

| Forging | Excellent | ||

| Uses | |||

| Ductile Alloy Suitable as Blanking, Riveting, Brazing and Upsetting | |||

Application Areas:

IS: 2074

BS: 2874 CZ119

IS: 4170/75

Cu Zn 38PB1 / 1.5.

Superior Machinability

BS 2872 CZ108 Riveting Leaded Brass is recognized for its exceptional machinability. The trace amount of lead present enhances chip formation, making the alloy easy to work with during cutting and shaping processes. This feature ensures consistently high productivity for manufacturing rivets, fasteners, and other engineering components.

Corrosion Resistance for Demanding Environments

CZ108 offers reliable corrosion resistance, particularly in mild atmospheric and marine conditions. The composition provides longevity and durability to hardware exposed to outdoor elements, supporting applications in marine hardware and general engineering projects where protection from environmental factors is essential.

Flexible Customization and Packaging

Available in both custom and standard lengths (up to 6 meters) and diameters ranging from 10 mm to 100 mm, CZ108 bars can be tailored to your project specifications. Packaged securely in bundles or wooden boxes, this material is safely transported and stored for various end uses across industries.

FAQs of BS 2872 CZ108 Riveting Leaded Brass:

Q: How is BS 2872 CZ108 Riveting Leaded Brass manufactured?

A: BS 2872 CZ108 is produced by alloying copper and zinc with trace amounts of lead under controlled conditions, resulting in a brass that meets the British Standard BS 2872. The material is then cast into round bars and subjected to tempering processes to achieve desired hardness levels.Q: What are the main applications of CZ108 Riveting Leaded Brass?

A: CZ108 is primarily used for making rivets, fasteners, marine hardware, and general engineering components. Its excellent machinability and corrosion resistance make it suitable for both hot and cold working, providing versatile performance in various industrial settings.Q: When should I choose quarter hard or half hard tempers for CZ108 bars?

A: Quarter hard (1/4H) and half hard (1/2H) tempers are selected based on mechanical strength and formability requirements. Quarter hard is ideal when some flexibility is needed, while half hard provides greater strength and rigidity, recommended for demanding fastening or structural tasks.Q: Where is CZ108 Riveting Leaded Brass typically sourced from?

A: CZ108 Riveting Leaded Brass is widely exported, manufactured, and supplied by leading brass producers in India, who cater to both domestic and international markets with customized lengths, diameters, and packaging types.Q: What benefits does the bright polished surface finish offer?

A: The bright, polished finish of CZ108 enhances its aesthetic appeal and provides an additional layer of protection against environmental factors. This finish is especially valued for components that require both mechanical performance and visual quality.Q: How does CZ108 perform in marine conditions?

A: CZ108 exhibits good corrosion resistance in mild marine environments, making it a reliable choice for marine hardware and applications exposed to humid or salty conditions. However, it is best suited for non-extreme marine settings.Q: What is the typical weight range and tolerance for CZ108 round bars?

A: The weight of CZ108 bars varies depending on the chosen diameter and length, with a standard dimensional tolerance of 0.01 mm. This ensures precision for engineering tasks and facilitates integration into automated manufacturing processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rivetting Leaded Brass Rods' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |