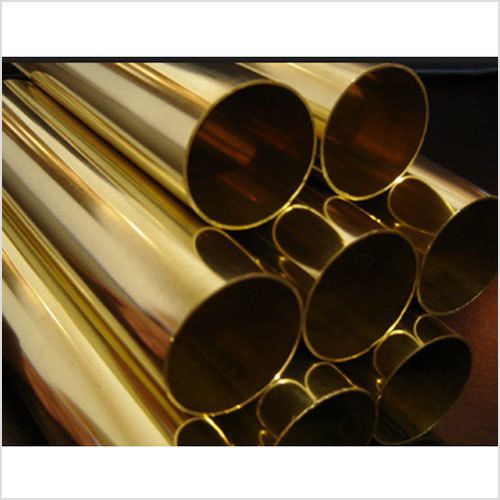

EN 12449 CW 507L 63-37 Lead Free Brass

Product Details:

- Type Lead Free Brass Rod

- Material Brass

- Grade EN 12449 CW507L

- Tolerance h8 to h13

- Alloy CW 507L (CuZn37)

- Temper Half Hard

- Length 2-6 meters

- Click to View more

EN 12449 CW 507L 63-37 Lead Free Brass Price And Quantity

- 380.00 - 480.00 INR/Kilograms

- 300 Kilograms

EN 12449 CW 507L 63-37 Lead Free Brass Product Specifications

- h8 to h13

- EN 12449 CW507L

- Half Hard

- As per size and length

- Lead Free Brass Rod

- Round

- CW 507L (CuZn37)

- Brass

- 4 mm to 90 mm

- 2-6 meters

- Golden

EN 12449 CW 507L 63-37 Lead Free Brass Trade Information

- 60000 Kilograms Per Month

- 3 Week

Product Description

EN 12449 CW 507L 63-37 Lead Free Brass

Being the leaders in the industry, we are engaged in manufacturing and exporting a varied

assortment of 70/30 Brass Tubes, Condenser Tubes. Precisely manufactured using premium grade

raw materials that are sourced from trusted & reliable dealers, the brass tubes offered by us are used

in various industries including, sugar & general engineering. Our 70/30 Brass Tubes are sturdy in

construction, easy to install, durable, corrosion proof and offered at nominal costs.

Application Area: Sugar Industries, Plumbing, Furniture, Hand Pumps, Ammunitions, General Engineering.

Technical Specifications :

| Specification : | |

| 70/30 Brass |

|

| S407/81 (SUGAR ALLOY I) | |

| Chemical Requirements | CuZn30As |

| Copper + Incidental Ni | 68.5 - 71.5% |

| Lead | 0.07% max |

| Arsenical | 0.02 to 0.06% |

| Iron | 0.06% max |

| Other Imp. | 0.30% max |

| Zinc | Remainder |

| Physical Properties | ||

| Condition | T.S. Mpa | Hardness (HV5) |

| Annealed (O) | 285 min | 75 max |

| Temper Annealed (TA) | 300 min | 80-110 |

| Hard (H) | 400 min | 135 min |

Further Tests :

Drift Test

Flattening Test

MN Test

Hydraulic Test

Uses : Condenser & heat exchangers tubes mainly for sugar plants, liner material for hand pumps

Premium Lead-Free Brass Solution

EN 12449 CW 507L 63-37 Lead Free Brass is tailored for industries seeking high-performance, environmentally responsible materials. Crafted in compliance with EN 12449 standards, this alloy is perfect for use in electrical, sanitary, and precision engineering components. Its bright, polished surface and durable properties ensure reliable application across a variety of sectors.

Superior Mechanical and Electrical Performance

Engineered for a balance of strength and ductility, this brass rod offers tensile strength of 290-360 MPa and a minimum elongation of 25%. With electrical conductivity rated at 25% IACS, it meets demanding industrial needs. The alloys half-hard temper and excellent machinability make it easy to process for both custom and standard parts.

Safe and Eco-Friendly Material Choice

With lead content below 0.1%, EN 12449 CW 507L 63-37 is a responsible choice for businesses prioritizing health and environmental safety. Its non-toxic profile aligns with global regulations for potable water, food contact, and sensitive electrical environments, offering peace of mind and regulatory compliance.

FAQs of EN 12449 CW 507L 63-37 Lead Free Brass:

Q: How is EN 12449 CW 507L 63-37 Lead Free Brass typically used in industry?

A: This lead-free brass is commonly used in the manufacturing of electrical connectors, sanitary fittings, and engineering components due to its excellent corrosion resistance, machinability, and compliance with health and safety standards.Q: What is the process for manufacturing components from CW 507L Lead Free Brass rods?

A: The rods can be cut, machined, or formed using conventional metalworking techniques. The alloys good machinability and half-hard temper allow for efficient processing into precise components suitable for various industrial applications.Q: When should I choose lead-free brass like EN 12449 CW 507L over traditional leaded brass?

A: Lead-free brass should be selected when environmental safety, regulatory compliance (for potable water or food contact), or reduced lead exposure is required. It is ideal for applications where public health or eco-friendly materials are essential.Q: Where are EN 12449 CW 507L 63-37 Lead Free Brass rods commonly supplied and exported from?

A: These brass rods are widely manufactured, supplied, and exported from India, serving customers globally in sectors such as electrical, engineering, and sanitary industries.Q: What benefits does this lead-free brass alloy provide compared to traditional brass?

A: It offers excellent corrosion resistance, high mechanical strength, and safer environmental profiles due to minimal lead content, ensuring compliance with international health and safety standards.Q: How does the surface finish impact the application of CW 507L brass rods?

A: The bright or polished finish not only enhances aesthetics but also improves resistance to corrosion and contamination, making it ideal for sanitary and electrical components.Q: What tolerances are available for EN 12449 CW 507L brass rods, and why are they important?

A: Tolerances range from h8 to h13, allowing for precise fit and compatibility in various engineering applications and assemblies. Tight tolerances ensure reliable performance and component interchangeability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in '63/37 Lead Free Brass Tubes & Rods' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |