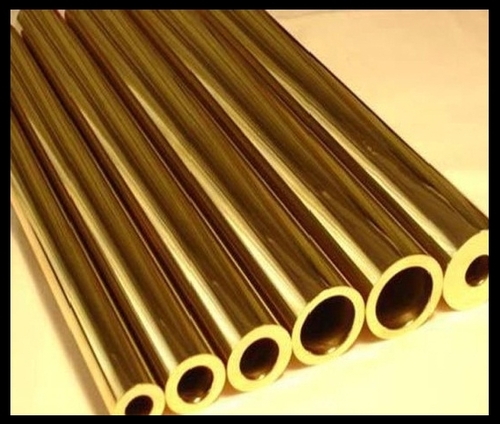

85-15 Red Brass Tube

Product Details:

- Product Type Red Brass Tube

- Material 85-15 Red Brass Alloy (85% Copper, 15% Zinc)

- Shape Round

- Technique Seamless / Extruded

- Thickness 0.5 mm - 10 mm (custom available)

- Alloy or Not Alloy

- Outer Diameter 6 mm - 150 mm

- Click to View more

85-15 Red Brass Tube Price And Quantity

- 500.00 - 700.00 INR/Kilograms

- 500 Kilograms

85-15 Red Brass Tube Product Specifications

- Up to 6 meters / custom cut lengths available

- Alloy

- Round

- Seamless / Extruded

- Red Brass Tube

- 6 mm - 150 mm

- 0.5 mm - 10 mm (custom available)

- Golden Yellow/Red Brass

- Customizable

- ASTM B135, ASTM B43, JIS H3300, EN 12451

- 85-15 Red Brass Alloy (85% Copper, 15% Zinc)

85-15 Red Brass Tube Trade Information

- 30000 Kilograms Per Month

- 4 Week

Product Description

85-15 Red Brass Tube

C23000 red brass 85% copper 15% zinc has very good resistance to corrosion and dezincification. C230 pipe is used in hot water lines, especially circulating systems, as the corrosiveness of any water increases with a rise in temperature. Red brass is the most durable of all metals for the plumbing industry and commercial water pipe applications. It is excellent for resistance to dezincification and season cracking which most high copper brasses are known for. Dezincification Resistant Alloys (also known as DZR or DR Alloys) such as Red Brass C352 has a small amount of arsenic added to the alloy in order to prevent chlorinated water from leaching the zinc from your plumbing products which eventually leads to the weakening and cracking of your plumbing products.

Red brass is also specified for underground service lines since it offers great corrosion resistance to all types of potable waters, and has moderate strength and good retention of spring properties.

Versatile Application Range

Whether for plumbing systems, heat exchangers, radiators, marine hardware, or decorative purposes, the 85-15 Red Brass Tube offers flexibility in diverse industries thanks to its customizable dimensions and temper choices. Crafted with corrosion resistance in mind, it ensures durability in challenging environments and adds an elegant golden yellow aesthetic to visible installations.

Superior Alloy Composition

Manufactured from an 85% copper and 15% zinc alloy, this red brass tube boasts high tensile strength (310-550 MPa), excellent elongation (25-40%), and a melting point of 900C 940C. The alloy composition, combined with seamless or extruded production techniques, guarantees robust performance, longevity, and reliable resistance to environmental factors such as water and marine exposure.

FAQs of 85-15 Red Brass Tube:

Q: How is the inner diameter of the 85-15 Red Brass Tube customized for specific requirements?

A: The inner diameter can be tailored according to customer requirements, ensuring optimal compatibility for different plumbing or engineering needs. Precise dimensions are achieved through seamless or extruded manufacturing techniques to match project specifications.Q: What makes the 85-15 Red Brass Tube suitable for marine and plumbing applications?

A: Its exceptional corrosion resistance, robust mechanical properties, and compliance with international standards like ASTM B135 and EN 12451 make it ideal for environments exposed to moisture, pressure, and corrosive agents commonly found in marine and plumbing systems.Q: When should a Hard, Half-Hard, or Soft temper be selected for red brass tubing?

A: The temper you choose depends on the mechanical requirements of your project: Hard provides maximum strength; Half-Hard offers a balance of flexibility and strength; Soft is recommended for situations that require easy bending or fabrication without compromising integrity.Q: Where is the 85-15 Red Brass Tube primarily manufactured and exported from?

A: This tube is primarily manufactured, supplied, and exported from India by specialized producers who ensure adherence to global standards and take care to offer customizable solutions and secure packaging for international shipments.Q: What processes are used in the production of 85-15 Red Brass Tubes?

A: The tubes are produced using seamless or extruded techniques, which enable the creation of custom lengths, thicknesses, and diameters. Polished or mill finishes are available per application needs, with each tube undergoing strict quality control for export.Q: How does using 85-15 Red Brass Tube benefit heat exchanger and radiator performance?

A: Its high thermal conductivity, resistance to corrosion, and adaptability in size and shape significantly improve the efficiency and lifespan of heat exchangers and radiators, making it a preferred choice for these components in industrial setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Red Brass Pipes & Tubes' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |