JIS H33000 C 2700 63-37 Lead Free Brass

Product Details:

- Type Lead Free Brass

- Material Copper-Zinc Alloy

- Grade JIS H3300 C2700

- Tolerance ±0.05mm

- Alloy C2700

- Temper Annealed / Hard

- Length Custom / Standard

- Click to View more

JIS H33000 C 2700 63-37 Lead Free Brass Price And Quantity

- 300 Kilograms

- 380.00 - 480.00 INR/Kilograms

- Lead Free (<0.01%)

- Electrical 25% IACS

- Cu 63%, Zn 37%

- Automotive, Electrical, Plumbing, Decorative

- 8.44 g/cm³

- 900°C - 940°C

- Non-magnetic

- Yes

- 75~105 HV

- JIS H3300

- Good

- Polished / Mill Finish

- Export Worthy Packing

JIS H33000 C 2700 63-37 Lead Free Brass Product Specifications

- Annealed / Hard

- ±0.05mm

- Yellowish Golden

- Depends on Dimensions

- Custom / Standard

- JIS H3300 C2700

- 4mm to 100mm

- Lead Free Brass

- C2700

- Round Bar / Rod

- Copper-Zinc Alloy

- Lead Free (<0.01%)

- Electrical 25% IACS

- Cu 63%, Zn 37%

- Automotive, Electrical, Plumbing, Decorative

- 8.44 g/cm³

- 900°C - 940°C

- Non-magnetic

- Yes

- 75~105 HV

- JIS H3300

- Good

- Polished / Mill Finish

- Export Worthy Packing

JIS H33000 C 2700 63-37 Lead Free Brass Trade Information

- 60000 Kilograms Per Month

- 3 Week

Product Description

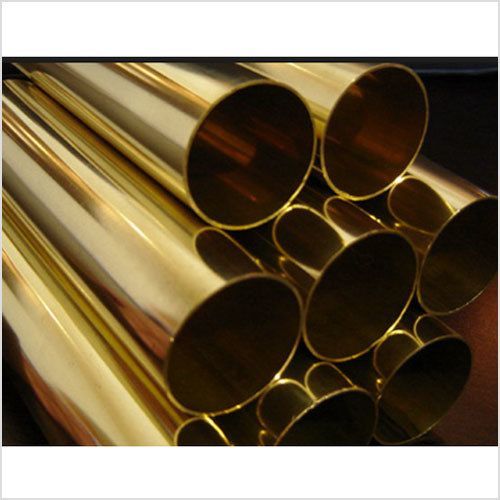

JIS H33000 C 2700 63-37 Lead Free Brass

Being the leaders in the industry, we are engaged in manufacturing and exporting a varied

assortment of 70/30 Brass Tubes, Condenser Tubes. Precisely manufactured using premium grade

raw materials that are sourced from trusted & reliable dealers, the brass tubes offered by us are used

in various industries including, sugar & general engineering. Our 70/30 Brass Tubes are sturdy in

construction, easy to install, durable, corrosion proof and offered at nominal costs.

Application Area: Sugar Industries, Plumbing, Furniture, Hand Pumps, Ammunitions, General Engineering.

Technical Specifications :

| Specification : | |

| 70/30 Brass |

|

| S407/81 (SUGAR ALLOY I) | |

| Chemical Requirements | CuZn30As |

| Copper + Incidental Ni | 68.5 - 71.5% |

| Lead | 0.07% max |

| Arsenical | 0.02 to 0.06% |

| Iron | 0.06% max |

| Other Imp. | 0.30% max |

| Zinc | Remainder |

| Physical Properties | ||

| Condition | T.S. Mpa | Hardness (HV5) |

| Annealed (O) | 285 min | 75 max |

| Temper Annealed (TA) | 300 min | 80-110 |

| Hard (H) | 400 min | 135 min |

Further Tests :

Drift Test

Flattening Test

MN Test

Hydraulic Test

Uses : Condenser & heat exchangers tubes mainly for sugar plants, liner material for hand pumps

Precision Engineering with Eco-Friendly Standards

JIS H33000 C 2700 63-37 Lead Free Brass stands out as a reliable choice for industries prioritizing sustainability without compromising on performance. Its lead-free composition makes it ideal for sensitive applications, while the grade and finishing options enhance its versatility across sectors like electronics, plumbing, and automotive manufacturing.

Versatile Applications for Modern Industries

Designed to meet a wide range of industry requirements, this brass alloy boasts high conductivity and corrosion resistance, making it suitable for parts where durability and appearance matter. Its customizable shape, temper, and size ensure seamless integration into both functional components and decorative elements.

FAQs of JIS H33000 C 2700 63-37 Lead Free Brass:

Q: What are the typical uses for JIS H33000 C 2700 63-37 Lead Free Brass?

A: This brass grade is utilized in automotive components, electrical connectors, plumbing fittings, and decorative hardware due to its excellent mechanical and corrosion-resistant properties.Q: How does the manufacturing process ensure the material remains lead free?

A: The alloy is produced using controlled smelting and refining processes to maintain lead content below 0.01%, ensuring compliance with RoHS and other global lead-free directives.Q: When should I choose this alloy over standard brass?

A: Opt for JIS H33000 C 2700 Lead Free Brass when lead content restrictions are in place or where environmental safety is a priority, such as in potable water systems and export-oriented products.Q: Where is this brass bar and rod typically sourced from?

A: It is commonly manufactured and exported by established suppliers in India, known for their adherence to JIS H3300 standards and export-worthy packaging practices.Q: What benefits does the polished or mill finish provide?

A: A polished finish enhances aesthetic appeal for decorative use, while a mill finish is preferred for components that undergo further machining or are used in non-visible applications.Q: How is the correct size and tolerance managed for custom orders?

A: Manufacturers adhere to strict tolerances (0.05mm) and offer custom or standard lengths and diameters ranging from 4mm to 100mm, ensuring the material meets precise project requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in '63/37 Lead Free Brass Tubes & Rods' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |