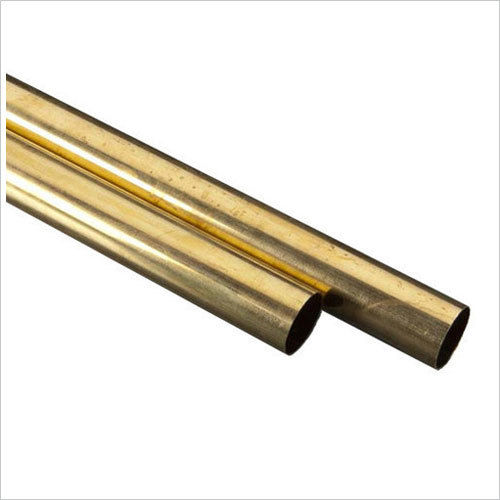

Admiralty Brass Tubes / Pipes

Product Details:

- Product Type Admiralty Brass Tubes / Pipes

- Material Admiralty Brass (Copper-Zinc-Tin Alloy)

- Shape Round

- Technique Seamless / Welded

- Thickness 0.5 mm to 10 mm

- Alloy or Not Alloy

- Outer Diameter 6 mm to 254 mm

- Click to View more

Admiralty Brass Tubes / Pipes Price And Quantity

- 430.00 - 550.00 INR/Kilograms

- 500 Kilograms

Admiralty Brass Tubes / Pipes Product Specifications

- Golden Yellow

- Admiralty Brass Tubes / Pipes

- Admiralty Brass (Copper-Zinc-Tin Alloy)

- 0.5 mm to 10 mm

- Seamless / Welded

- ASTM B111, B16, B395 or Equivalent

- 6 mm to 254 mm

- Alloy

- Up to 6 meters or Custom

- Customizable as per requirement

- Round

Admiralty Brass Tubes / Pipes Trade Information

- 50000 Kilograms Per Month

- 4 Week

Product Description

We bring forth for our clients an exhaustive gamut of Aluminum Brass Tubes, Aluminum Brass Tubing which is preferred across the globe owing to its superior quality, durability and accurate dimensions. As aadmiralty brass tubes manufacturer in India, we manufacture thetubes using cutting edge techniques and excellent quality raw materials that are procured from trusted & reliable vendors. To ensure confirmation with the ISO standards, the entire range of Aluminum Brass Tubes is examined by adroit quality controllers before final delivery. Clients can buy these tubes from us at industry leading prices.

Technical Specifications :

|

Specification : |

|

Admiralty Brass Tubes |

|

|

|

|

Salient features:

-

Rugged construction

-

Durable finish standards

-

Accurate dimensions

-

Corrosion resistance

Application Areas:

-

Automobile Industry

-

General Engineering Purposes

-

Industrial Refrigeration

-

Heat Exchanger

-

Radiator

-

Condenser Copper Tubes

-

Evaporator Copper Tubes

Product Details :

|

Minimum Order Quantity |

200 Kilogram |

|

Technique |

Cutting Edge |

|

Application |

Heat Exchanger, Industrial etc |

|

Shape |

Tube |

|

Material |

Aluminium And Brass |

Other Details :

|

Standard |

BS 2871 PART3 |

ASTM B 111 |

DIN 1785 |

NFA 51 102 |

JIS H3300 |

IS 1545 |

|

Symbol |

CZ 111 |

C 44300 |

CuZn28Sn1 |

CuZn29Sn1 |

C 4430 |

CuZn29Sn1As |

|

Cu |

70.0-73.0 |

70.0-73.0 |

70.0-72.5 |

70.0-73.0 |

70.0-73.0 |

70.0-73.0 |

|

Sn |

1.0-1.5 |

0.9-1.2 |

0.9-1.3 |

0.9-1.2 |

0.9-1.2 |

1.0-1.5 |

|

Pb |

0.07 |

0.07 |

0.07 |

0.07 |

0.07 |

0.07 |

|

Ni |

- |

- |

0.1 |

- |

- |

- |

|

Fe |

0.06 |

0.06 |

0.07 |

0.06 |

0.06 |

0.06 |

|

Zn |

REMDER |

REMDER |

REMDER |

REMDER |

REMDER |

REMDER |

|

As |

0.02-0.06 |

0.02-0.06 |

0.02-0.035 |

0.02-0.06 |

0.02-0.06 |

0.02-0.06 |

|

P |

- |

- |

0.01 |

- |

- |

- |

|

Total Impurities Max. |

|

|

|

|

- |

|

|

|

0.03 |

- |

0.1 |

0.3 |

- |

0.3 |

|

Condition |

M |

61 |

F36 |

- |

- |

O |

|

|

TA |

- |

F32 |

- |

O |

TA |

|

|

O |

- |

- |

- |

- |

D |

|

Yield Strength N/MM2 |

- |

- |

140-220 |

- |

- |

- |

|

|

- |

105 |

100-170 |

- |

- |

- |

|

Tensile N/MM2 Minimum |

- |

310 |

360 |

- |

- |

375 Mpa Max. |

|

|

- |

- |

320 |

- |

314Min. |

340 Mpa Min. |

|

|

- |

- |

- |

- |

- |

385 Mpa Min. |

|

ElngTion Percent (%) Minimum |

- |

- |

45Min. |

- |

-. |

- |

|

|

- |

- |

55Min. |

- |

30 Min. |

- |

|

Hardness HV5 - |

150Min |

- |

- |

- |

- |

80 Max. |

|

|

85-105 |

- |

- |

80-120 |

- |

80-105 |

|

|

75Max. |

- |

- |

- |

- |

130 Min. |

|

Grain Size mm (75X) |

0.05Max. |

0.010-0.045 |

- |

0.010-0.045 |

0.010-0.045 |

0.010-0.04 |

Superior Corrosion Resistance for Industrial Demands

Admiralty Brass Tubes/Pipes excel in resisting corrosion, especially in harsh environments such as seawater and steam. This makes them an optimal choice for heat exchangers, condensers, and evaporators in diverse industries, ensuring longevity and reliability in continuous operations.

Customization for Precision Engineering

These tubes and pipes can be tailored to meet precise project requirements, including specific sizes, end types, and finishes. Seamless or welded construction options allow flexibility, while a choice between hard, half-hard, or soft tempers provides adaptability for different mechanical and thermal needs.

FAQs of Admiralty Brass Tubes / Pipes:

Q: How are Admiralty Brass Tubes suitable for high-pressure applications?

A: Admiralty Brass Tubes are designed with a robust copper-zinc-tin alloy composition, making them well-suited for high-pressure operations in industrial processes. Their adherence to international standards (ASTM B111, B16, B395) guarantees safety and reliability under demanding conditions.Q: What corrosion resistance benefits do Admiralty Brass Tubes offer?

A: These tubes provide exceptional resistance to corrosion, particularly from seawater and steam. This feature prolongs tube life and minimizes maintenance in environments such as power plants and sugar industries where exposure to aggressive media is common.Q: Where can Admiralty Brass Tubes be used effectively?

A: They are widely employed in heat exchangers, condensers, evaporators, and related systems across industries like power generation, sugar manufacturing, and chemical processing, thanks to their durability and conductive properties.Q: What is the process to customize Admiralty Brass Tubes for specific requirements?

A: Customization is available upon request, allowing for selection of specific diameters, thicknesses, lengths (up to 6 meters), end types (plain, threaded, beveled), and finishes. Clients can specify requirements during order placement for tailored solutions.Q: How does the seamless or welded technique influence the tubes performance?

A: The seamless technique offers enhanced strength and leak-proof performance, ideal for critical applications. The welded option provides cost-effective solutions where exceptionally high integrity is not compulsory, while both techniques maintain excellent corrosion resistance.Q: When should hard, half-hard, or soft temper tubes be chosen?

A: The selection depends on the mechanical and thermal requirements of your application. Hard temper tubes provide higher strength, suitable for high-pressure scenarios, while half-hard and soft tempers offer greater flexibility for easier bending or forming during installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Admiralty Brass Tubes' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |