IS 4413 CuZn37 Riveting Leaded Brass

Product Details:

- Type Riveting Leaded Brass

- Material Brass

- Grade IS 4413

- Tolerance 0.02 mm

- Alloy CuZn37

- Temper Half Hard

- Length Custom Lengths Available

- Click to View more

IS 4413 CuZn37 Riveting Leaded Brass Price And Quantity

- 500 Kilograms

- 400.00 - 600.00 INR/Kilograms

IS 4413 CuZn37 Riveting Leaded Brass Product Specifications

- 0.02 mm

- Riveting Leaded Brass

- 1 mm to 100 mm

- Half Hard

- As per requirement

- Brass

- IS 4413

- Custom Lengths Available

- Round Bar

- Yellowish Golden

- CuZn37

IS 4413 CuZn37 Riveting Leaded Brass Trade Information

- 50000 Kilograms Per Month

- 3 Week

Product Description

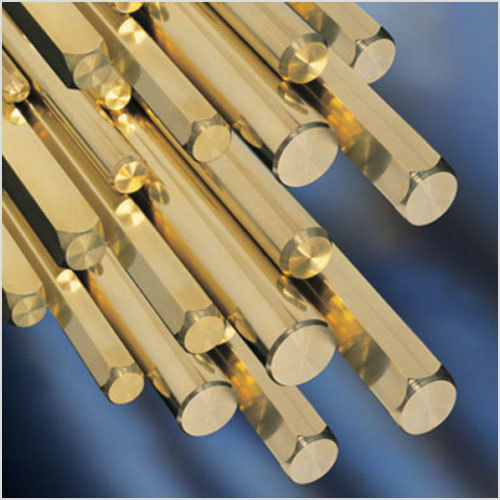

IS 4413 CuZn37 Riveting Leaded Brass

e are one of the well recognized manufacturers and exporters of a sturdily designed array of Riveting Brass Rods. These are machined in sync with the industrial norms using modern machinery and excellent grade raw materials. Available in diverse specifications and at pocket friendly prices, our Riveting Brass Rods are well known across the global market owing to their incomparable performance, high conductivity, corrosion resistance and low maintenance.

| Specification : | |

| Riveting Brass |

|

| Chemical Requirements | CuZn40 | ||

| Copper | 59.0 - 62.0% | ||

| Lead | 0.75% max. | ||

| Iron | 0.10% max. | ||

| Total Imp. Excl. Iron | 0.300% max. | ||

| Zinc | Remainder | ||

| Physical Properties | |||

| Condition | Size mm | T.S.Kg/mm2 | EL% Min |

| Annealed (O) | 1.2 & above | 28 min. | 30% |

| As Manufactured | 1.2 & above | 35 min. | 25% |

| Fabrication Properties | |||

| Capacity for being | |||

| Machinability Rating | 55% | ||

| Bending | Excellent | ||

| Riveting | Excellent | ||

| Forging | Excellent | ||

| Uses | |||

| Ductile Alloy Suitable as Blanking, Riveting, Brazing and Upsetting | |||

Application Areas:

IS: 2074

BS: 2874 CZ119

IS: 4170/75

Cu Zn 38PB1 / 1.5.

Key Features

IS 4413 CuZn37 Riveting Leaded Brass stands out for its excellent machinability, enabling precise and efficient fabrication of various components. With a density of 8.5 g/cm and a conductivity rating of 23% IACS, it supports versatile electrical and mechanical applications. The alloys good corrosion resistance and bright surface finish make it ideal for both functional and aesthetic purposes.

Applications and Uses

This brass alloy finds widespread utilization in riveting, the production of fasteners, and electrical component manufacturing. Its superior machinability and precise tolerance control allow fabricators to produce consistent, high-quality parts. Custom lengths and diameters make it adaptable to diverse industry needs, from automotive to electronics.

Manufacturing and Supply

Produced by leading exporters, manufacturers, and suppliers in India, IS 4413 CuZn37 Riveting Leaded Brass is available in round bar form and multiple diameters. Every batch is packed using export-worthy methods to guarantee safe transit. The alloys composition and temper are strictly controlled to maintain quality and performance standards.

FAQs of IS 4413 CuZn37 Riveting Leaded Brass:

Q: How is IS 4413 CuZn37 Riveting Leaded Brass typically used in industry?

A: This alloy is predominantly used in the manufacturing of rivets, fasteners, and electrical components due to its excellent machinability and consistent performance. Its bright finish and corrosion resistance also suit decorative or exposed parts.Q: What is the process for manufacturing components with IS 4413 CuZn37 brass?

A: Components are manufactured by machining rods, bars, or wires into the desired shapes and sizes. The alloys half-hard temper and tight tolerances allow for efficient and precise machining, making it suitable for high-volume production.Q: When should I choose IS 4413 CuZn37 Leaded Brass over other alloys?

A: Select this alloy when you require fine machinability, reliable mechanical properties, good electrical conductivity, and resistance to general corrosionespecially for rivets and electrical fittings where precision is critical.Q: Where is IS 4413 CuZn37 Riveting Leaded Brass manufactured and supplied from?

A: This alloy is produced and exported by established manufacturers and suppliers in India. It is available globally, with packaging designed for secure international shipping.Q: What forms and sizes are available for IS 4413 CuZn37 Riveting Leaded Brass?

A: The brass alloy is available in rods, bars, and wires, with diameters ranging from 1 mm to 100 mm, and custom lengths. Tolerances are maintained at 0.02 mm for precise fit and finish.Q: How does the lead content in IS 4413 CuZn37 benefit its machinability?

A: The addition of up to 1.5% lead improves chip formation during machining, reduces tool wear, and enables smoother and faster processing, making it highly desirable for mass production.Q: What are the key benefits of using IS 4413 CuZn37 brass in fasteners and electrical components?

A: Key advantages include excellent machinability, consistent dimensional accuracy, good corrosion resistance, a bright finish, and sufficient electrical conductivity, all essential for quality and durable fasteners or electrical parts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rivetting Leaded Brass Rods' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |