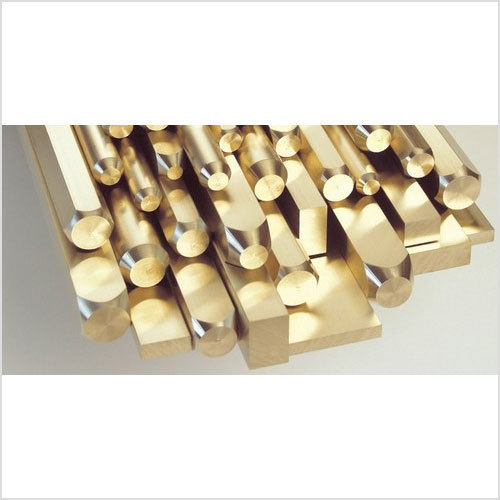

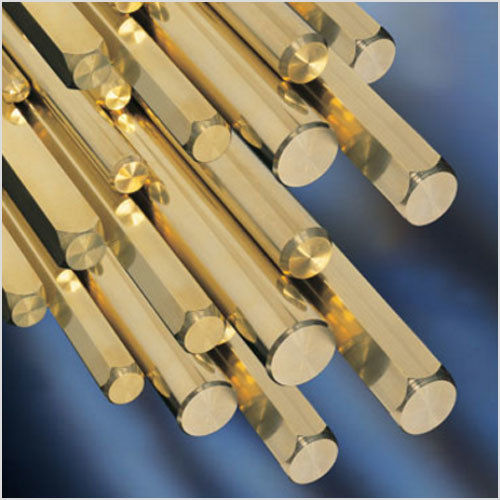

Profile and Flats Brass Rods

400.00 - 1000.00 INR

Product Details:

- Type Profile and Flats Brass Rods

- Material Brass

- Grade Cz121, CW614N

- Tolerance 0.05 mm

- Alloy IS 319 / BS 2874 / CZ121 / CW614N

- Temper Hard, Half Hard, Annealed

- Length Up to 6 meters

- Click to View more

X

Profile and Flats Brass Rods Price And Quantity

- 400.00 - 1000.00 INR

- 500 Kilograms

Profile and Flats Brass Rods Product Specifications

- Up to 6 meters

- Golden Yellow

- IS 319 / BS 2874 / CZ121 / CW614N

- Brass

- Hard, Half Hard, Annealed

- As per length and diameter

- Profiles and Flats

- Cz121, CW614N

- 0.05 mm

- 4 mm to 50 mm

- Profile and Flats Brass Rods

Profile and Flats Brass Rods Trade Information

- 150 Kilograms tons Per Month

- 3 to 4 Week

Product Description

We are one of the eminent manufacturers, suppliers and exporters of a large array of Profile, Extruded Brass Profiles and Flats Brass Rods. These are manufactured by our experienced professionals using modern machinery and premium grade raw materials that are sourced from dependable dealers. Owing to their rigid construction, precise dimensions, excellent performance, high conductivity and corrosion resistance, these Profile and Flats Brass Rods find applications in diverse industries.

Specifics :

BS249

IS: 319 Gr. l & ll

IS: 8364 Gr. l & ll

BS: 2874 CZ121Pb3

CuZn39Pb3

Exceptional Material Properties

Our Profile and Flats Brass Rods are crafted from premium brass alloys such as IS 319, BS 2874, CZ121, and CW614N. With hardness between 65 and 90 HRB and a density of 8.4 g/cm, they provide robust strength while maintaining excellent corrosion resistance and a brilliant golden yellow finish. These features make them suitable for demanding applications across various industries.

Versatile Applications and Customization

These brass rods serve a wide range of sectors, from electrical and engineering to decorative and hardware uses. Their outstanding machinability and tolerance of 0.05 mm enable intricate designs and precise fitting. Customized dimensions and surface finishes can be supplied upon request, catering to unique project requirements.

Reliable Supply and Export Packaging

Produced, supplied, and exported from India, our brass rods are securely packed in export-worthy wooden boxes or bundles to maintain integrity during transit. Clients benefit from a streamlined process, with lead times typically ranging from 2 to 4 weeks after placing a purchase order.

FAQs of Profile and Flats Brass Rods:

Q: How is the hardness level of Profile and Flats Brass Rods beneficial for different applications?

A: The hardness range of 65 to 90 HRB ensures these brass rods can withstand mechanical stress, making them suitable for both structural and decorative uses. Hard and half hard tempers provide versatility for electrical, hardware, and engineering applications that demand durability.Q: What process is followed to manufacture these brass rods to standard specifications?

A: Profile and Flats Brass Rods are manufactured using established brass alloys (IS 319, CZ121, CW614N) and conform to ASTM B16 and EN 12167 standards. Advanced processes such as hot or cold extrusion, followed by precise annealing or tempering, ensure smooth and bright surface finishes with tight tolerances.Q: When can customers expect delivery after placing a purchase order?

A: Lead time for delivery varies between 2 to 4 weeks from the date of purchase order, depending on customization and volume required. This ensures efficient processing and timely shipment worldwide.Q: Where can these brass rods be used most effectively?

A: These rods are ideal in electrical wiring, engineering components, decorative fixtures, and various hardware items due to their machinability, corrosion resistance, and aesthetic appeal. Their robust surface finish and precise dimensions facilitate widespread adoption across industries.Q: What packaging is provided for export shipments to ensure product safety?

A: Every shipment is packed in export-worthy wooden boxes or bundles, designed to protect the brass rods from damage and environmental factors during transit, ensuring products arrive in excellent condition.Q: How does the excellent machinability of the rods benefit end users?

A: Good machinability allows users to easily shape, cut, and fabricate the rods into complex components or precise fittings. This reduces tooling costs and enhances assembly efficiency in industries such as electrical, engineering, and decorative hardware.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Brass Rods & Profiles' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |