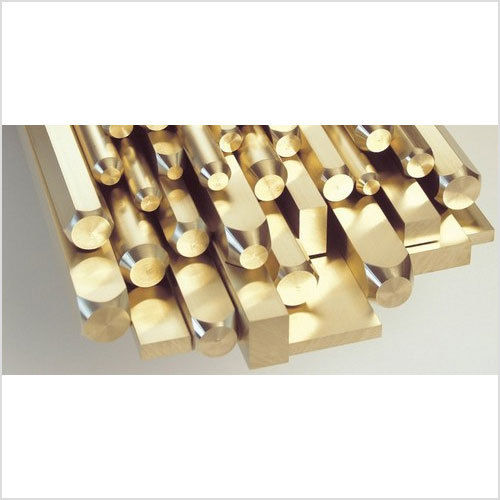

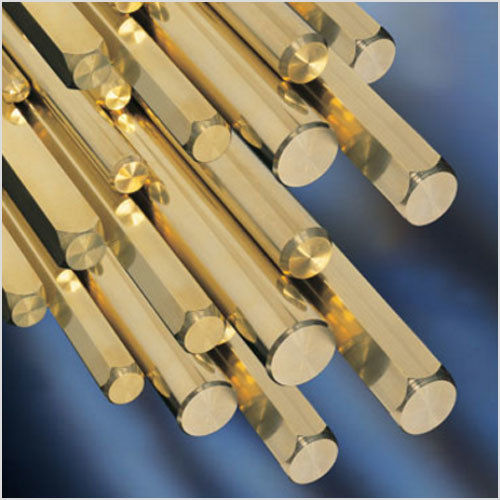

Free Cutting Brass Rods

Product Details:

- Type Free Cutting Brass Rods

- Material Brass

- Grade CW614N / CZ121

- Tolerance h9, h11 or as required

- Alloy IS 319 / BS 249 / CZ121 / CW614N

- Temper Half Hard / Hard / Annealed

- Length 3 m (standard), custom lengths available

- Click to View more

Free Cutting Brass Rods Price And Quantity

- 400.00 - 1000.00 INR

- 500 Kilograms

Free Cutting Brass Rods Product Specifications

- CW614N / CZ121

- Golden Yellow

- Half Hard / Hard / Annealed

- Brass

- IS 319 / BS 249 / CZ121 / CW614N

- h9, h11 or as required

- Round / Hexagonal / Square

- 3 mm to 80 mm

- Varies as per size and length

- 3 m (standard), custom lengths available

- Free Cutting Brass Rods

Free Cutting Brass Rods Trade Information

- 150 Kilograms tons Per Month

- 3 to 4 Week

Product Description

Free Cutting Brass Rods

We specialize in manufacturing and exporting our clients a robustly designed range of Free Cutting Brass Rods. These are durable, corrosion resistant and available in different grades, thicknesses and dimensions. Our Free Cutting Brass Rods are manufactured from quality proven raw materials to ensure excellent performance, high conductivity and longer operational life.

Specifications:

BS249

IS: 319 Gr. l & ll

IS: 8364 Gr. l & ll, BS: 2874 CZ121Pb3

CuZn39Pb3

| Chemical Requirements | Grade I | |

| Copper | 56.0 - 59.0% | |

| Lead | 2.0 to 3.50% | |

| Iron | 0.35% max. | |

| Total Imp. Excl. Iron | 0.70% max. | |

| Zinc | Remainder | |

| Physical Properties | |||

| Condition | Size | T.S. MPA | EL% Min |

| Annealed (O) | 6-25 | 345 | 12 |

| Half-Hard (HB) | 6-12 | 405 | 4 |

| Hard (HD) | 6-12 | 550 | - |

| Fabrication Properties | |

| Capacity for being | |

| Cold worked | Poor |

| Cold worked | Poor |

| Hot formed | Fair |

| Machinability Rating | 100% |

| Suitability for soldering | Excellent |

| Suitability for Brazing | Good |

| Uses | |

| Precision Components, Hardware, Hinges, Lock Bodies, Screws, Nuts & Bolts | |

| Chemical Requirements | Grade II | Grade III |

| Copper | 60.0 - 63.0% | 60.0 - 63.0% |

| Lead | 2.50 to 3.70% | 0.50 to 1.50% |

| Iron | 0.35% max | 0.20% max |

| Total Imp. Excl. Iron | 0.50% max | 0.50% max |

| Zinc | Remainder | Remainder |

| Physical Properties | |||||

| Condition | Size | T.S. MPA | EL% Min | T.S. MPA | EL% Min |

| Annealed (O) | 6-25 | 355 | 15 | 315 | 22 |

| Half-Hard (HB) | 6-12 | 395 | 7 | 355 | 8 |

| Hard (HD) | 6-12 | 550 |

| 460 |

|

| Fabrication Properties | |||

| Capacity for being | |||

| Cold worked | Poor | Fair | |

| Hot formed | Fair | Excellent | |

| Machinability Rating | 90% | 80% | |

| Suitability for soldering | Excellent | Excellent | |

| Suitability for Brazing | Good | Excellent | |

| Uses |

| Gr II : Gear, Pinions, Precision, Automobile, Electronic Parts |

| Gr III : Precision Components Machining with Riveting Operation |

Superior Machinability and Finish

Free Cutting Brass Rods are designed with precision in mind, offering an outstanding finish that is both bright and polished. The rods provide excellent workability during machining processes, reducing tool wear and ensuring precise results. Their smooth surface helps maintain accuracy in manufacturing, making them the preferred choice for high-precision parts.

Exceptional Corrosion Resistance

Engineered for durability, these brass rods provide superior resistance to corrosion, making them ideal for challenging environments including electrical and automotive applications. Their high-quality alloy composition ensures longevity, even under exposure to moisture and chemicals, safeguarding the integrity of your finished products.

Versatile Applications Across Industries

Used in a wide range of industries, Free Cutting Brass Rods are well-suited for manufacturing precision components, hardware, electrical fittings, and automotive parts. Their adaptability in terms of shape, temper, and size allows manufacturers to select the ideal configuration for their specific project needs.

FAQs of Free Cutting Brass Rods:

Q: How are Free Cutting Brass Rods manufactured to ensure a smooth and polished finish?

A: Free Cutting Brass Rods are produced using high-precision drawing and extrusion techniques, followed by finishing processes such as polishing to achieve a bright, smooth, and clean surface ideal for high-quality applications.Q: What makes these brass rods suitable for precision components and electrical fittings?

A: These rods offer superior machinability and excellent dimensional tolerance (h9, h11 or as required), allowing for intricate shaping without compromising quality. Their corrosion resistance and smooth surface make them reliable for precision applications such as electrical fittings and intricate hardware.Q: When should I choose Free Cutting Brass Rods over other metal alternatives?

A: Free Cutting Brass Rods are preferable when projects demand excellent machinability, bright appearance, superior corrosion resistance, and tight tolerances, especially in the manufacturing of precision parts for automotive, hardware, and electrical sectors.Q: Where can these brass rods be supplied from, and what packaging options are available?

A: Our brass rods are exported and supplied directly from India, with packaging options including wooden cases, bundled forms, or customized packaging as per client requirements to ensure safe transportation and handling.Q: What is the process for customizing rod dimensions or alloy grades?

A: Clients can specify their required length, diameter, alloy grade, temper, or tolerance at the time of order. The manufacturer will tailor the rods according to these specifications, based on standards like IS, BS, EN, ASTM, or JIS, ensuring compatibility with your project needs.Q: How does the lead content affect the performance of Free Cutting Brass Rods?

A: Lead content (2.03.5% as per alloy) improves machinability by lubricating cutting tools during machining. It results in smoother cuts and reduced wear, making these brass rods ideal for high-speed, precision manufacturing.Q: What are the primary benefits of using Free Cutting Brass Rods in industrial applications?

A: Key benefits include superior corrosion resistance, excellent machinability, high tensile strength (360500 N/mm), versatility in shapes and sizes, compliance with international standards, and consistent quality, ensuring optimal performance in demanding environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Brass Rods & Profiles' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |