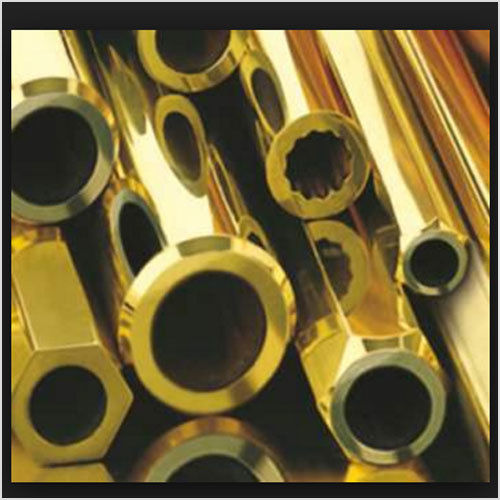

Forging Hollow Rods

Product Details:

- Usage Industrial Valves, Defense components

- Finish Polished

- Application Automobile Valves Components

- Material Forging Brass Rods

- Alloy No

- Temper Hard

- Shape Round

- Click to View more

Forging Hollow Rods Price And Quantity

- 500 Kilograms

- 400.00 - 1000.00 INR/Kilograms

Forging Hollow Rods Product Specifications

- Polished

- Automobile Valves Components

- Forging Brass Rods

- Round

- No

- Industrial Valves, Defense components

- Hard

Forging Hollow Rods Trade Information

- 150 Kilograms Per Month

- 3 -4 Week

Product Description

Forging Hollow Rods

These hollow rods are mainly used in manufacturing forged components and pressing materials and hence used mainly in making valve components..

Industry using forging hollow rods are forged components, industrial valves, defense components, watch case and automobile valves components.

Technical Specifications :

|

Specification : |

|

|

Forging Hollow Rods |

|

|

Chemical Requirements |

CuZn42Pb2 |

"CuZn40Pb2 " |

|

Copper |

56.5 - 60.0% |

"57.0 - 59.0% " |

|

Lead |

0.60 to 2.0% |

"1.5 to 2.5% " |

|

Iron |

0.30% max |

"0.40% max " |

|

Total Imp. Excl. Iron |

0.20% max |

0.70% max |

|

Zinc |

Remainder |

Remainder |

|

Physical Properties |

||

|

Tensile Strength |

380 Mpa Min |

"40 kg/mm2 Min. " |

|

Elongation % |

25% Min |

"18% Min. " |

|

Izod Value |

- |

2.0 KJ min |

Uses : Forged Components, Industrial Valves, Defense components, Watch Case, Automobile Valves Components.

Precision Engineering for Critical Valves

Our forging hollow rods are meticulously crafted from pure forging brass, ideal for components where precision, strength, and longevity are vital. These rods undergo stringent quality checks, resulting in consistent performance, a polished appearance, and the resilience required for industrial and defense applications. Manufactured in India, they meet global standards for valve manufacturing.

Versatility Meets Durability

These round, hard-tempered hollow rods seamlessly integrate into automotive and industrial valve assemblies, as well as defense equipment. Their polished surface and robust composition not only add to the visual appeal but also enhance operational efficiency and resistance to wear, making them a top choice for demanding sectors.

FAQs of Forging Hollow Rods:

Q: How are forging hollow rods used in automobile valve components?

A: Forging hollow rods are precision-shaped to create sturdy and reliable automobile valve components. Their hard temper and robust brass structure ensure the valves operate efficiently under high pressure and temperatures, common in automotive engine systems.Q: What is the manufacturing process of these forging hollow rods?

A: The rods are crafted through a forging process where brass is heated and shaped into hollow, round profiles. After forging, they are hardened and polished to achieve a durable finish suitable for critical industrial and defense applications.Q: When should one prefer non-alloyed, polished forging brass rods for valve applications?

A: Non-alloyed, polished forging brass rods are preferred when mechanical strength, corrosion resistance, and a smooth finish are essential. They are ideal for environments where reliability and longevity of valve components are paramount.Q: Where are these forging hollow rods typically utilized?

A: These rods are widely used in manufacturing automobile valves, industrial valve systems, and defense components. Their properties make them suitable for sectors that require high-quality and dependable valve parts.Q: What benefits do polished, hard-tempered forging brass rods offer?

A: Polished, hard-tempered brass rods offer increased strength, enhanced corrosion resistance, and excellent visual appeal. These characteristics contribute to longer component life and superior performance in challenging operating conditions.Q: How can manufacturers or suppliers in India support global requirements for these rods?

A: Manufacturers and suppliers in India export high-quality forging hollow rods worldwide, ensuring adherence to international standards. Their expertise and robust supply chain enable reliable delivery and technical support wherever required.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Leaded Brass Hollow Rods' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |