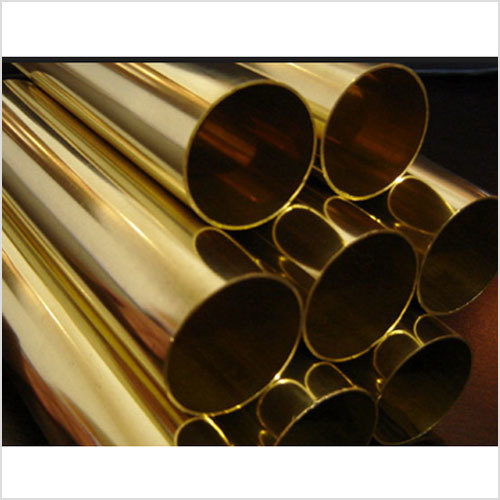

63/37 Brass Tubes

Product Details:

- Product Type Brass Round Tube

- Material Brass

- Shape Round

- Technique Cold Rolled

- Thickness 0.3 mm to 5 mm

- Alloy or Not Non-Alloy

- Outer Diameter 3 mm to 100 mm

- Click to View more

63/37 Brass Tubes Price And Quantity

- 500 Kilograms

- 400.00 - 1000.00 INR

63/37 Brass Tubes Product Specifications

- Golden Yellow

- 2000 mm (standard), can be customized

- Brass

- Round

- Non-Alloy

- Cold Rolled

- Customized, as per requirement

- Brass Round Tube

- ASTM B135, IS 319, IS 407, DIN, JIS, BS

- 3 mm to 100 mm

- 0.3 mm to 5 mm

63/37 Brass Tubes Trade Information

- 150 Kilograms tons Per Month

- 3 to 4 Week

Product Description

We are one of the leading manufacturers, exporters and suppliers of a complete line of 63/37 Brass Tubes. These are manufactured by adept technicians in accordance to the set domain guidelines & norms to ensure excellent performance, durability, rugged construction, reliable operation and corrosion resistance. Available in both standard & customized forms, our 63/37 Brass Tubes are affordable in prices and find usage in diverse industries across the globe.

| Specification : | |

| 63/37 Brass |

|

IS407/81 (SUGAR ALLOY I & COMMON ALLOY II)

| Chemical Requirements | CuZn30As | CuZn37 |

| Copper + Incidental Ni | 68.5 - 71.5% | 62.0 - 65.0% |

| Lead | 0.07% max | 0.30% max |

| Arsenical | 0.02 to 0.06% | 0.06% mac |

| Iron | 0.06% max | 0.10% max |

| Other Imp. | 0.30% max | 0.06% max |

| Zinc | Remainder | Remainder |

| Physical Properties | ||||

| Condition | T.S. MPa | Hardness | T.S. MPa | Hardness |

| Annealed (O) | 285 min | 75 max | 285 min | 80 max |

| Temper Annealed (TA) | 300 min | 80-110 | 320 min | 80-110 |

| Hard (H) | 400 min | 135min | 400 min | 130min |

Further Tests

Drift Test

Flattening Test

MN Test

Hydraulic Test

Uses

Gr 1 : Condenser & heat exchangers tubes mainly for sugar plants, liner material for hand pumps.

Gr 2 : Transmission aerials, Stove burner, decorative articles, hardware

Superior Material & Mechanical Properties

Manufactured from premium 63/37 (CuZn37) brass alloy, these tubes feature a golden yellow color, exceptional tensile strength (250-400 MPa), and elongation properties (15-30%). The excellent hardness (60-70 HRB) ensures durability and longevity for demanding industrial environments. Their high corrosion resistance makes them suitable for both indoor and outdoor use.

Versatile Applications Across Industries

63/37 Brass Tubes are commonly used in heat exchangers, plumbing systems, electrical parts, decorative pieces, and various industrial processes. The combination of high electrical and thermal conductivity with excellent formability makes these tubes a preferred choice for manufacturers and engineers alike.

Customizable Manufacturing for Specific Needs

With a cold-rolled manufacturing process, the tubes can be customized in terms of thickness (0.35 mm), outer diameter (3100 mm), and lengths as per requirements. Available finishes include bright, smooth polished surfaces, and end finishes can be specified as plain, deburred, or threaded to meet precise technical demands.

FAQs of 63/37 Brass Tubes:

Q: How are the 63/37 Brass Tubes manufactured and finished?

A: These tubes are produced using a cold-rolled technique which ensures a bright, smooth surface and enhanced mechanical properties. The end finish can be customized as plain, deburred, or threaded, depending on specific applications or customer requirements.Q: What are the primary applications for 63/37 Brass Tubes?

A: These tubes are used in heat exchangers, plumbing, electrical components, decorative elements, and a variety of industrial processes due to their durability, corrosion resistance, and conductive properties.Q: When should I choose annealed, half hard, or hard temper brass tubes?

A: Selecting the temper depends on your project needs: annealed tubes offer high formability for bending and shaping; half hard provides a balance of strength and flexibility; and hard temper is suitable for applications where greater strength and rigidity are required.Q: Where can these brass tubes be installed?

A: Thanks to their excellent corrosion resistance and high conductivity, the tubes are suitable for both indoor and outdoor installations, in demanding industrial, residential, or commercial environments.Q: What sizes and lengths are available for order?

A: Outer diameters range from 3 mm to 100 mm, with thicknesses between 0.3 mm and 5 mm. The standard length is 2000 mm, but custom dimensions can be manufactured to suit specific requirements.Q: How do these brass tubes benefit electrical and heat exchange applications?

A: The high electrical and thermal conductivity of CuZn37 brass ensures efficient energy transfer, while its non-alloy composition and excellent corrosion resistance prolong service life in electrical and heat exchange systems.Q: What standards do these brass tubes comply with?

A: They are manufactured to meet ASTM B135, IS 319, IS 407, DIN, JIS, and BS standards, ensuring reliable quality and dimensional accuracy for global markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Lead Free Brass Tubes' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |