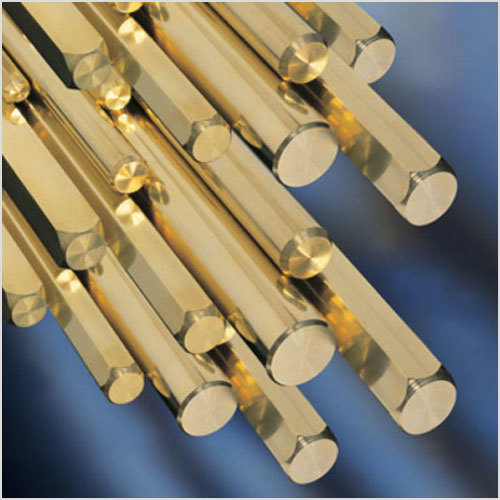

BS 2874 CZ109 Riveting Leaded Brass

Product Details:

- Type Riveting Leaded Brass Rods

- Material Brass

- Grade BS 2874 CZ109

- Tolerance +/-0.05 mm

- Alloy CZ109

- Temper 1/2 Hard

- Length 3 m (standard), custom length available

- Click to View more

BS 2874 CZ109 Riveting Leaded Brass Price And Quantity

- 500 Kilograms

- 400.00 - 600.00 INR/Kilograms

BS 2874 CZ109 Riveting Leaded Brass Product Specifications

- 3 mm to 100 mm

- Variable, depends on diameter and length

- Round

- Yellowish Brass

- 3 m (standard), custom length available

- Brass

- BS 2874 CZ109

- Riveting Leaded Brass Rods

- 1/2 Hard

- CZ109

- +/-0.05 mm

BS 2874 CZ109 Riveting Leaded Brass Trade Information

- 50000 Kilograms Per Month

- 3 Week

Product Description

BS 2874 CZ109 Riveting Leaded Brass

e are one of the well recognized manufacturers and exporters of a sturdily designed array of Riveting Brass Rods. These are machined in sync with the industrial norms using modern machinery and excellent grade raw materials. Available in diverse specifications and at pocket friendly prices, our Riveting Brass Rods are well known across the global market owing to their incomparable performance, high conductivity, corrosion resistance and low maintenance.

| Specification : | |

| Riveting Brass |

|

| Chemical Requirements | CuZn40 | ||

| Copper | 59.0 - 62.0% | ||

| Lead | 0.75% max. | ||

| Iron | 0.10% max. | ||

| Total Imp. Excl. Iron | 0.300% max. | ||

| Zinc | Remainder | ||

| Physical Properties | |||

| Condition | Size mm | T.S.Kg/mm2 | EL% Min |

| Annealed (O) | 1.2 & above | 28 min. | 30% |

| As Manufactured | 1.2 & above | 35 min. | 25% |

| Fabrication Properties | |||

| Capacity for being | |||

| Machinability Rating | 55% | ||

| Bending | Excellent | ||

| Riveting | Excellent | ||

| Forging | Excellent | ||

| Uses | |||

| Ductile Alloy Suitable as Blanking, Riveting, Brazing and Upsetting | |||

Application Areas:

IS: 2074

BS: 2874 CZ119

IS: 4170/75

Cu Zn 38PB1 / 1.5.

High Precision and Quality

Our BS 2874 CZ109 Riveting Leaded Brass Rods deliver precision with tight tolerances of +/-0.05 mm and a bright, polished finish. Their consistent quality ensures reliable performance in demanding engineering environments and the fastener industry.

Versatile Applications

CZ109 brass rods are ideal for manufacturing rivets, screws, and fasteners due to their excellent machinability and durability. Their corrosion resistance allows them to perform effectively in various engineering projects and environments.

Customizable Options

With standard lengths of 3 meters and diameters from 3 mm to 100 mm, these rods can be tailored to specific needs. Custom lengths and sizes are available upon request, ensuring solutions for project-specific requirements.

FAQs of BS 2874 CZ109 Riveting Leaded Brass:

Q: How is BS 2874 CZ109 Riveting Leaded Brass typically used in industry?

A: BS 2874 CZ109 Riveting Leaded Brass is predominantly used in manufacturing fasteners, rivets, screws, and components for general engineering. Its excellent machinability and corrosion resistance make it ideal for applications requiring precision and durability.Q: What is the process for manufacturing CZ109 Riveting Leaded Brass rods?

A: CZ109 rods are produced by alloying copper, lead, and zinc according to the specified chemical composition. The alloy is cast, hot rolled or extruded, and then drawn or machined to precise diameters, followed by polishing for a bright finish and cut to required lengths.Q: When should I choose CZ109 brass rods over other alloys?

A: CZ109 should be selected when excellent machinability, good corrosion resistance, and a bright surface finish are essential. It is particularly suitable for fasteners, rivets, and applications that demand easy fabrication and high mechanical strength.Q: Where are BS 2874 CZ109 rods exported and supplied from?

A: These rods are manufactured, supplied, and exported from India, where leading manufacturers ensure adherence to the BS 2874 standard and provide customized dimensions for international and domestic markets.Q: What are the main benefits of using CZ109 Riveting Leaded Brass in fastener production?

A: The main benefits include superior machinability, reliable mechanical properties, good corrosion resistance, and an attractive polished appearance, all of which optimize production efficiency and end-product longevity.Q: How does the temper 1/2 Hard influence the rods performance?

A: The 1/2 Hard temper strikes a balance between ductility and strength, offering moderate hardness for forming operations while providing sufficient resilience for structural or fastening applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Rivetting Leaded Brass Rods' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |