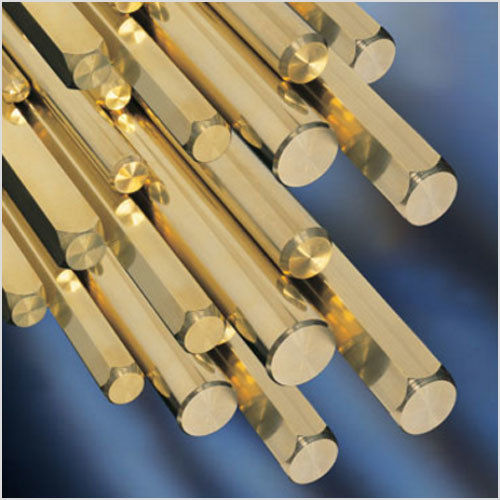

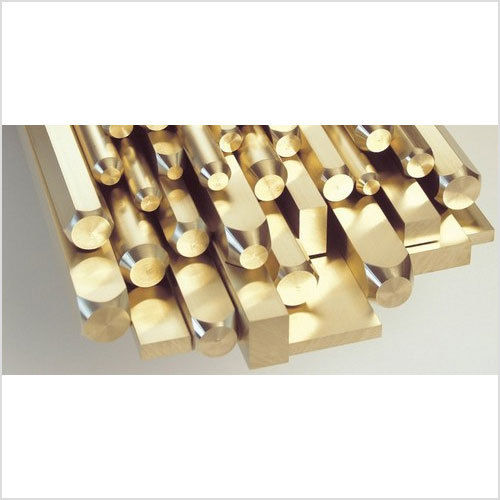

Naval Brass Rods

Product Details:

- Material Brass

- Grade HIgh

- Alloy Yes

- Temper 1/2 Hard

- Shape Round

- Click to View more

Naval Brass Rods Price And Quantity

- 500 Kilograms

- 400.00 - 1000.00 INR/Kilograms

Naval Brass Rods Product Specifications

- 1/2 Hard

- Yes

- Brass

- HIgh

- Round

Naval Brass Rods Trade Information

- 150 Kilograms Per Month

- 3 - 4 Week

Product Description

We are one of the eminent manufacturers, suppliers and exporters of Naval Brass Rods. These are manufactured by our experienced professionals using modern machinery and premium grade raw materials that are sourced from dependable dealers.

| Chemical Requirements | Grade I | Grade II |

| Copper | 61.0 - 64.0% | 59.0 - 62.0% |

| Lead | 0.20% max | 0.50 to 1.0% |

| Tin | 1.0 to 1.50% | 0.50 to 1.0% |

| Iron | 0.10% max | - |

| Other Imp. | 0.20% max | 0.20% max |

| Zinc | Remainder | Remainder |

| Physical Properties | |||||

| Condition | Size | T.S. Kg/mm2 | EL% Min | T.S. Kg/mm2 | EL% Min |

| Half-Hard (HB) | Upto 12.5 | 40 min | 18% | 40 min | 15% |

| Fabrication Properties | |||

| Capacity for being | |||

| Cold worked | Fair | Poor | |

| Hot Worked | Excellent | Good | |

| Machinability Rating | 30% | 50% | |

| Forgeability Rating | 90% | 90% | |

| Silver Alloy Brazing | Excellent | Good | |

| Soft Soldering | Excellent | Excellent | |

| Oxyacetylene Welding | Good | Not Suitable | |

| Uses |

| Gr I : Condenser Components, Propeller Shaft, Marine hardware where bending is required. |

| Gr II : Marine Hardware, Screw Machine, Valve Stems and Components for Naval use. |

Superior Engineering for Marine Applications

Naval brass rods with a high-grade alloy, round profile, and 1/2 hard temper are specifically engineered to withstand the challenging conditions of marine environments. Their enhanced corrosion resistance and mechanical strength make them ideal for shipbuilding, hardware, and fittings exposed to seawater.

Quality Manufacturing and Export Expertise

As a reputed exporter, manufacturer, and supplier in India, we adhere to strict manufacturing protocols to ensure consistent quality. Our state-of-the-art facilities and experienced workforce enable us to meet international standards, fulfilling bulk orders with prompt delivery for global clients.

FAQs of Naval Brass Rods:

Q: How are naval brass rods with a 1/2 hard temper manufactured?

A: These rods are produced through a process that involves alloying copper and zinc, with a small amount of tin, followed by controlled rolling or drawing. The 1/2 hard temper is achieved by partial cold-working, imparting both strength and moderate ductility suitable for machining and fabrication.Q: What are the main uses of round naval brass rods in industrial applications?

A: Round naval brass rods are commonly used in marine hardware, propeller shafts, fasteners, heat exchanger tubes, and fittings, owing to their strength, machinability, and corrosion resistance. They are also chosen for electrical and architectural components where durability is required.Q: When should high-grade, alloyed naval brass rods be selected over standard brass rods?

A: High-grade alloyed naval brass rods should be selected when projects demand improved tensile strength, enhanced resistance to corrosion (especially from saltwater), and superior fabrication qualities. They are particularly recommended for marine and heavy-duty industrial applications.Q: Where are naval brass rods supplied and exported from in India?

A: Naval brass rods are supplied and exported across major industrial hubs in India, including Mumbai, Chennai, and Kolkata, and shipped internationally from these locations. We manage both domestic distribution and overseas export through a network of reliable logistic partners.Q: What is the benefit of choosing a 1/2 hard temper for naval brass rods?

A: A 1/2 hard temper offers an optimal balance of strength, workability, and resistance to deformation. This makes the rods suitable for further machining or bending, without sacrificing their mechanical integrity or surface finish, which is essential for precise engineering components.Q: How does the manufacturing process ensure high-quality naval brass rods?

A: We implement stringent quality control at every stagefrom raw material selection to final inspectionutilizing modern machinery and skilled oversight. Regular testing ensures compliance with industrial standards and guarantees that each batch exhibits uniformity in composition and properties.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Brass Rods & Profiles' category

|

METAL ALLOYS CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |